In the field of modern power electronics, inverter technology has become the core link of energy conversion, and the difference between pure sine wave inverters and modified sine wave inverters directly determines their market positioning and application scenarios. Although modified sine wave inverters occupy the low-end and mid-end markets at a lower cost, high-end application fields - such as medical equipment, precision instruments, high-end home appliances and critical infrastructure - almost all choose pure sine wave inverters. This article will deeply analyze the essential differences between the two technologies and reveal the fundamental reasons why the high-end market insists on using pure sine wave inverters.

What is a sine wave inverter?

Sine wave inverter is a kind of inverter. It is a power electronic device that converts DC power (power battery, storage battery) into AC power (generally 220V, 50Hz sine wave). The inverter and ACDC converter are opposite processes. Since the ACDC converter or power adapter rectifies 220V AC power into DC power for use, and the inverter has the opposite function, it is named after it.

Sine wave inverter is an energy conversion device that converts DC power into AC power. It completes the inverter task by turning on and off power semiconductor devices according to specific rules. Modern inverter technology is a science that studies the theory, application and design methods of inverter circuits. It is a practical technology based on scientific foundations such as industrial electronic technology, semiconductor device technology, modern control technology, modern power electronics technology, pulse width modulation technology, semiconductor conversion technology and magnetic materials. Therefore, the application of sine wave inverter runs through many fields of society and life.

What is a Modified Sine Wave Inverter?

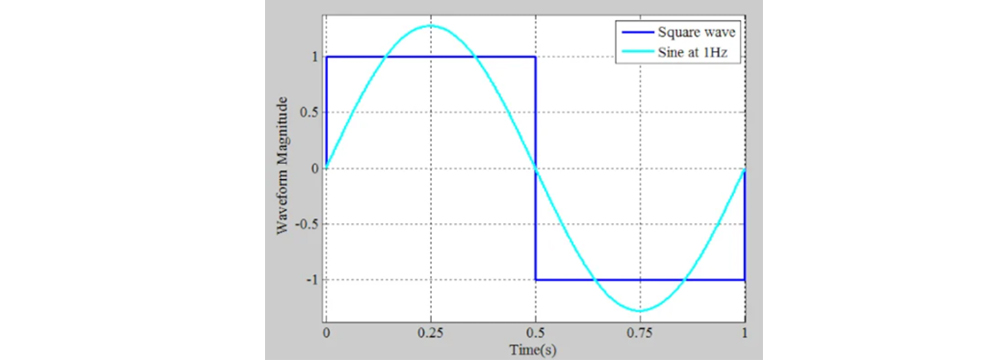

Modified sine wave is relative to sine wave, the output waveform of mainstream inverter, i.e. modified sine wave. There are two main types of inverter waveforms, sine wave inverters (i.e. pure sine wave inverters) and square wave inverters. A sine wave inverter outputs the same or even better sine wave alternating current than the grid we use every day, because it does not have the electromagnetic pollution in the grid.

The main differences between pure sine wave and modified sine wave inverters are in output waveform, efficiency, applicability and cost.

Output waveform Pure sine wave inverters usually use PWM (pulse width modulation) technology, and some products also incorporate multi-step inversion design. The output waveform is of high quality, close to the AC power of the mains grid, and suitable for inductive and capacitive loads

Modified sine wave inverters mainly use square wave inversion, and a few products add step inversion. The output waveform quality is poor, and the adaptability to inductive and capacitive loads is weak

Efficiency Pure sine wave inverters show higher efficiency due to their stable sine wave output and the application of high-frequency technology, and are suitable for various loads

Modified sine wave inverters due to the need The output waveform needs to be modified when the current flows, resulting in lower efficiency.

Applicability Pure sine wave inverters are suitable for inductive loads, capacitive loads and resistive loads, and can drive various devices that can be connected to the mains. They are suitable for precision instruments and communication equipment, etc.

Modified sine wave inverters are mainly suitable for resistive loads, such as incandescent lamps, electric heaters, etc., but they have poor adaptability to inductive loads and capacitive loads, and may generate loud noise and cause damage to electrical appliances

Cost Pure sine wave inverters are relatively expensive due to their complex structure and high technical requirements Modified sine wave inverters have a simple structure and a lower price

The core reason why the high-end market chooses pure sine waves

1. Compatibility guarantee for sensitive equipment

Precision equipment in high-end application scenarios is extremely sensitive to power quality. Medical equipment such as CPAP ventilators and oxygen concentrators, if powered by modified sine waves, may cause control circuit misjudgment, sensor reading drift, and even damage to key components. Similarly, IT infrastructure such as servers and data centers require pure power to avoid data errors, and the high-frequency noise of modified sine waves may cause abnormal reading and writing of storage devices or network transmission errors.

Laboratory instruments such as spectrometers and electron microscopes have strict restrictions on power ripple (usually requiring <1%). The voltage mutation of modified sine waves will cause measurement benchmark drift, seriously affecting the repeatability of experimental results. In contrast, pure sine waves can provide a stable waveform that is indistinguishable from the mains, ensuring that the equipment operates in the best condition.

2. Performance optimization of motor loads

High-end home appliances (such as variable frequency refrigerators, air conditioners, and washing machines) generally use high-efficiency AC motors, which will have obvious problems when powered by modified sine waves:

Starting torque decreases: The harmonics of modified sine waves will cause magnetic field distortion, reducing the starting torque by 30%-50%, which may cause the compressor to fail to start normally

Increased operating noise: The vibration caused by harmonics increases the motor noise by 5-15 decibels, affecting the user experience

Significant temperature rise: Harmonic currents produce additional copper losses in the windings, causing the motor temperature to rise by 20%-40%, shortening the service life

The same is true in the electric vehicle field. Electric vehicle motors controlled by pure sine waves run more smoothly, with significantly reduced noise and vibration, while modified sine wave control has slightly higher energy efficiency (about 5%-10%), but the comfort is greatly reduced. In the high-end electric vehicle market, the driving experience takes precedence over the slight difference in energy efficiency.

3. System reliability and life considerations

High-end users pay more attention to long-term use costs rather than initial investment. Pure sine wave inverters perform better in the following aspects:

Less stress on power electronic devices: Smooth waveforms reduce the dV/dt stress of the switch tube (MOSFET/IGBT), and the failure rate is reduced by 40%-60%

Extended capacitor life: Low harmonics mean reduced ripple current of the filter capacitor, and the life of the electrolytic capacitor can be extended by 3-5 times

Better battery protection: Pure sine wave inverters are usually equipped with more precise charge and discharge management, which increases the number of battery cycles by 20%-30%

Key areas such as medical and communications pay particular attention to system availability. As described in web page 2, the DC panel of the power system with a pure sine wave inverter can achieve an ultra-long service life of 10-15 years, while ordinary UPS systems often have the situation of "battery damage but not discovered in time" due to the use of modified sine waves and lack of maintenance.

4. Comprehensive advantages of energy efficiency

Although the efficiency of modified sine wave inverters is slightly higher (about 1%-3%) when no-load or light-loaded, in actual applications:

Pure sine wave has higher comprehensive energy efficiency for inductive loads (such as motors) because it reduces iron and copper losses caused by harmonics

In photovoltaic systems, pure sine wave inverters have higher MPPT (maximum power point tracking) accuracy, and the annual power generation can be increased by 5%-8%

High-end pure sine wave products use industrial-grade IGBTs, and the conduction loss is 30%-40% lower than the MOSFET commonly used in modified sine wave inverters

Applicable scenarios and limitations of modified sine wave inverters

Despite the obvious advantages of pure sine wave, modified sine wave inverters still have a certain market in the following scenarios:

Basic lighting system: LED lights, fluorescent lights =Resistive loads that are not sensitive to waveforms

Simple electronic devices: mobile phone chargers, laptop adapters and other devices with built-in rectifier circuits

Temporary power supply occasions: construction sites, field operations and other environments that do not require high power quality

However, its inherent limitations make it difficult to enter the high-end market:

Unable to drive precision motors: As described on page 3, if equipment such as well pumps use modified sine wave inverters, they must be equipped with an additional "soft start control box" or replaced with a relay-type control box, otherwise it may cause startup failure

Medical equipment risks: As emphasized on page 4, life support equipment such as CPAP may damage sensitive components using modified sine waves, posing a risk of medical accidents

Audio and video interference: High harmonics can cause background noise in the sound system, causing ripple interference on the display

The choice of the high-end market reflects the consideration of comprehensive value rather than pure price. Although the initial investment of pure sine wave inverters is higher, their advantages in equipment compatibility, system reliability, energy efficiency and user experience make them the only viable choice in fields such as medical care, data centers, high-end manufacturing and smart homes. With technological progress and economies of scale, pure sine wave technology is gradually penetrating into the mid-end market, a trend that will further consolidate its dominant position in the high-end market.

Share our interesting knowledge and stories on social media