In terms of power supply, everyone may know that frequency converter and variable frequency power supply are auxiliary equipment for charging electrical appliances, but many people do not understand what variable frequency power supply is and what variable frequency power supply is. With the continuous progress of the times, electrical appliances will also be constantly updated, and auxiliary equipment is also constantly changing. Below we will learn in detail the difference between frequency converter and variable frequency power supply.

Variable frequency power supply has been developed since the 1980s, and the technology has been perfected. However, there are still many people who know little about it and do not understand what the variable frequency power supply does.

1. Working principle and function of variable frequency power supply

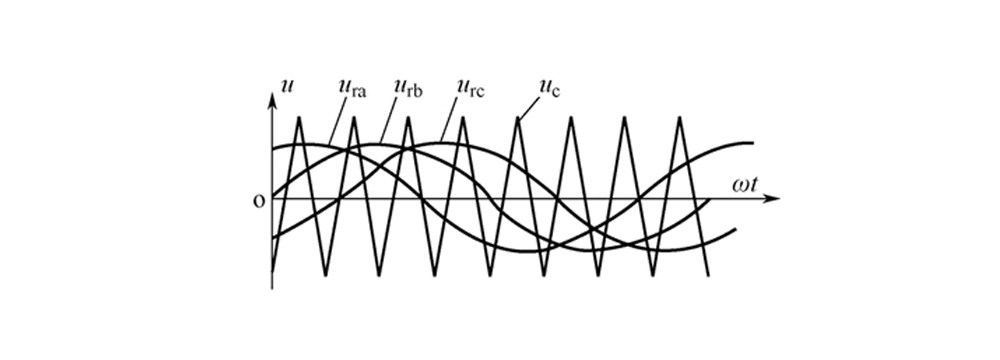

In layman's terms, variable frequency power supply is a variable frequency device composed of "AC → DC → AC → filter" circuit, which can convert AC to mains power, adjust a certain range of frequency and voltage, simulate different output grid indicators, and provide pure and reliable, low harmonic distortion, high stability of voltage and frequency sine wave power output.

The variable frequency power supply is based on a microprocessor and uses power electronic semiconductor devices as power output units. It uses FPGA digital control, instantaneous waveform control, high-frequency sinusoidal pulse width modulation (SPWM), digital frequency division, D/A conversion, instantaneous value feedback, IGBT output and other new technologies and modular structures to ensure reliable operation of the power supply.

The power supply has the advantages of fast response speed, strong load adaptability, high output accuracy, high efficiency, superior waveform quality, simple operation, small size and light weight. At the same time, it has human protection functions such as overcurrent, overload, overheating and short circuit, ensuring safety and efficiency during use.

The variable frequency power supply is highly professional and is widely used in the simulation of power supply voltage of power grids in various countries in the world. It is generally used in home appliance manufacturing, motors, electronic manufacturing, IT industry, computer equipment, laboratories, etc. (for example: motors, refrigerators, air conditioners, washing machines, soymilk machines and other manufacturers) for production, testing, experiments, etc. It can also be used for power supply protection in the development stage of any AC power supply product.

2. How to choose a variable frequency power supply

So how do we choose a variable frequency power supply?

2.1 First of all, from the perspective of technical services

From a technical perspective, we try to choose variable frequency power supplies produced by source manufacturers, with their own R&D strength and production capabilities, manufacturers with good pre-sales, in-sales and after-sales services, and whether they have non-standard customization capabilities.

2.2 Variable frequency power supply load characteristics

We must consider whether the variable frequency power supply has strong load characteristics, especially whether it can carry inductive loads. Let's take a 1000VA variable frequency power supply as an example (600W hand drill, 750W hand grinder cutting machine are all inductive loads, which must be able to drive smoothly). Other resistive, capacitive, and mixed loads can also be easily loaded.

2.3 Variable frequency power supply output frequency

The output frequency range of the variable frequency power supply is 40-500Hz, which can be adjusted online. Choose according to your actual requirements, and pay special attention to the output frequency range.

2.4 Variable frequency power supply impact resistance

The impact resistance of the variable frequency power supply is also a point we must consider, and how strong the impact energy is.

2.5 Other matters for selecting variable frequency power supply

The output must be pure sine waveform, with fast response speed, high precision, simple operation, remote control, stability and durability, etc.

3. What is a frequency converter

Variable-frequency Drive (VFD) is a power control device that uses frequency conversion technology and microelectronics technology to control AC motors by changing the frequency of the motor's working power supply.

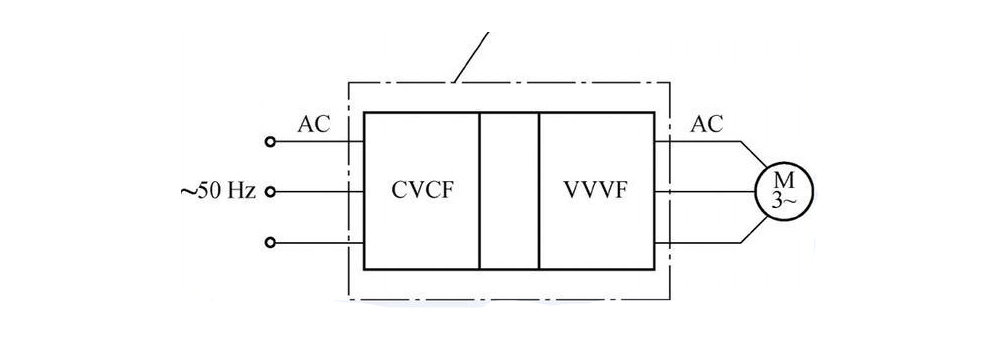

The frequency converter is mainly composed of rectification (AC to DC), filtering, inversion (DC to AC), braking unit, drive unit, detection unit, microprocessor unit, etc. The frequency converter adjusts the voltage and frequency of the output power supply by the internal IGBT disconnection, and provides the required power supply voltage according to the actual needs of the motor, thereby achieving the purpose of energy saving and speed regulation. In addition, the frequency converter has many protection functions, such as overcurrent, overvoltage, overload protection, etc. With the continuous improvement of the degree of industrial automation, frequency converters have also been widely used.

4 Functions of frequency converters

Frequency conversion energy saving

The energy saving of frequency converters is mainly reflected in the application of fans and water pumps. After the fan and pump loads adopt variable frequency speed regulation, the power saving rate is 20% to 60%. This is because the actual power consumption of the fan and pump loads is basically proportional to the cube of the speed. When the average flow required by the user is small, the fan and pump adopt variable frequency speed regulation to reduce their speed, and the energy saving effect is very obvious. Traditional fans and pumps use baffles and valves to adjust the flow, the motor speed is basically unchanged, and the power consumption does not change much. According to statistics, the power consumption of fan and pump motors accounts for 31% of the national power consumption and 50% of industrial power consumption. It is of great significance to use variable frequency speed regulation devices on such loads. At present, the more successful applications are constant pressure water supply, various fans, central air conditioners and hydraulic pumps.

Application in automation system

Because the inverter has a built-in 32-bit or 16-bit microprocessor, has a variety of arithmetic logic operations and intelligent control functions, the output frequency accuracy is 0.1%~0.01%, and is equipped with a complete detection and protection link, it is widely used in automation systems. For example: winding, stretching, metering, and wire guiding in the chemical fiber industry; flat glass annealing furnaces, glass kiln mixing, edge drawing machines, and bottle making machines in the glass industry; automatic charging and batching systems for arc furnaces, and intelligent control of elevators. Application of frequency converters in improving process levels and product quality Application of frequency converters in CNC machine tool control, automobile production lines, papermaking, and elevators.

Application in improving process levels and product quality

Frequency converters can also be widely used in various mechanical equipment control fields such as transmission, lifting, extrusion, and machine tools. It can improve process levels and product quality, reduce equipment impact and noise, and extend the service life of equipment. After adopting variable frequency speed control, the mechanical system is simplified, and operation and control are more convenient. Some can even change the original process specifications, thereby improving the function of the entire equipment. For example, the temperature of the setting machine used in textiles and many industries is adjusted by changing the amount of hot air supplied. A circulating fan is usually used to transport hot air. Since the fan speed remains unchanged, the amount of hot air supplied can only be adjusted by the damper. If the damper fails to adjust or is improperly adjusted, the shaping machine will be out of control, thus affecting the quality of the finished product. The circulating fan starts at high speed, and the wear between the transmission belt and the bearing is very severe, making the transmission belt a consumable. After adopting variable frequency speed regulation, temperature regulation can be achieved by the frequency converter automatically adjusting the speed of the fan, solving the problem of product quality. In addition, the frequency converter can easily start the fan at low frequency and low speed and reduce the wear between the transmission belt and the bearing. It can also extend the service life of the equipment and save energy by 40%.

Realize motor soft start

The hard start of the motor will not only cause serious impact on the power grid, but also require too high power grid capacity. The large current and vibration generated during startup will cause great damage to the baffle and valve, and are extremely detrimental to the service life of the equipment and pipelines. After using the frequency converter, the soft start function of the frequency converter will make the starting current change from zero, and the maximum value will not exceed the rated current, which reduces the impact on the power grid and the requirements for power supply capacity, extends the service life of the equipment and valves, and also saves equipment maintenance costs.

5. Selection of frequency converter

The type of frequency converter to be selected depends on the type of production machinery, speed regulation range, static speed accuracy, and starting torque requirements. The so-called suitable frequency converter should be easy to use and economical to meet the basic conditions and requirements of process and production.

The motor to be controlled and the frequency converter itself

5.1 Number of poles of the motor. Generally, the number of motor poles should not exceed (, otherwise the inverter capacity should be appropriately increased.

5.2 Torque characteristics, critical torque, acceleration torque. Under the same motor power, the inverter specifications can be selected at a reduced rating compared to the high overload torque mode.

5.3 Electromagnetic compatibility. In order to reduce the interference of the main power supply, a reactor can be added to the intermediate circuit or the inverter input circuit, or a pre-isolation transformer can be installed. Generally, when the distance between the motor and the inverter exceeds 50m, a reactor, a filter or a shielded protective cable should be connected between them.

Selection of inverter power

The system efficiency is equal to the product of the inverter efficiency and the motor efficiency. Only when both are working at a higher efficiency, the system efficiency is higher. From the perspective of efficiency, when selecting the inverter power, pay attention to the following points:

1) It is most appropriate when the inverter power value is equivalent to the motor power value, so that the inverter can operate at a high efficiency value.

2) When the power classification of the inverter is different from that of the motor, the power of the inverter should be as close to that of the motor as possible, but should be slightly larger than that of the motor.

3) When the motor is frequently started, braked, or started under heavy load and works frequently, a larger inverter can be selected to utilize the inverter for long-term and safe operation.

4) After testing, if the actual power of the motor is indeed surplus, you can consider using an inverter with a power smaller than that of the motor, but pay attention to whether the instantaneous peak current will cause overcurrent protection.

5) When the power of the inverter is different from that of the motor, the setting of the energy-saving program must be adjusted accordingly to achieve a higher energy-saving effect.

5.4 Selection of inverter box structure

The box structure of the inverter must be adapted to the environmental conditions, that is, factors such as temperature, humidity, dust, pH, and corrosive gases must be considered. There are several common structural types for users to choose from:

1) The open IPOO type has no chassis itself and is suitable for installation in the electric control box or on the screen, panel, or rack in the electrical room. Especially when multiple inverters are used together, this type is better, but the environmental conditions are required to be high;

2) The closed IP20 type is suitable for general use, and there may be a small amount of dust or a little temperature and humidity;

3) The sealed IP45 type is suitable for environments with poor industrial site conditions;

4) The sealed IP65 type is suitable for environments with poor environmental conditions, such as water, dust, and certain corrosive gases.

5.5 Determination of inverter capacity

Reasonable capacity selection itself is an energy-saving and consumption-reducing measure. According to existing data and experience, there are three relatively simple methods:

1) Determination of the actual power of the motor. First, measure the actual power of the motor to select the capacity of the inverter.

2) Formula method. When a frequency converter is used for multiple motors, it should meet the following requirements: at least the influence of the starting current of one motor should be considered to avoid the inverter from tripping due to overcurrent.

3) Motor rated current method inverter.

The inverter capacity selection process is actually a process of optimal matching between the inverter and the motor. The most common and safest method is to make the inverter capacity greater than or equal to the rated power of the motor. However, in actual matching, the actual power of the motor should be considered to be different from the rated power. Usually, the selected capacity of the equipment is too large, while the actual required capacity is small. Therefore, it is reasonable to select the inverter according to the actual power of the motor to avoid selecting an inverter that is too large and increasing the investment. For light loads, the inverter current should generally be selected according to 1.1N (N is the rated current of the motor), or according to the maximum motor power matched with the output power rating of the inverter indicated by the manufacturer in the product.

5.6 Main power supply

1) Power supply voltage and fluctuation. Special attention should be paid to adapting to the inverter low voltage protection setting value, because in actual use, the possibility of low grid voltage is greater.

2) Main power frequency fluctuation and harmonic interference. This interference will increase the heat loss of the inverter system, resulting in increased noise and reduced output.

3) The power consumption of the inverter and the motor when they are working. When designing the main power supply of the system, the power consumption factors of both should be taken into account

6. The difference between the inverter and the variable frequency power supply

6.1 Different functions

The variable frequency power supply is used to convert the frequency of the input power supply into different frequency outputs to meet the working requirements of the equipment; the inverter is used to control the speed of the motor.

6.2 Different outputs

The variable frequency power supply outputs the power frequency and voltage; the inverter outputs the AC power with adjustable frequency.

6.3 Different applications

The variable frequency power supply is widely used in power systems, industrial equipment and electronic equipment; the inverter is widely used in industrial drive systems.

6.4 Different composition

The variable frequency power supply usually includes a transformer, a rectifier circuit and an inverter circuit; the inverter usually includes a rectifier, an inverter and a control circuit.

6.5 Different purposes

The purpose of the variable frequency power supply is to provide a stable power frequency and voltage; the purpose of the inverter is to control the speed of the motor. It should be noted that although variable frequency power supply and frequency converter are two different concepts, there is a certain connection between them. Frequency converter usually requires variable frequency power supply as its input power supply to provide voltage with variable frequency. Therefore, variable frequency power supply can be regarded as a part of frequency converter, which is used to provide power for frequency converter.

Share our interesting knowledge and stories on social media