Voltage stabilizer is an important device for regulating voltage stability and is often used in power systems and other fields.

1. So what is a voltage stabilizer?

A power voltage stabilizer is a power supply circuit or power supply equipment that can automatically adjust the output voltage. Its function is to stabilize the power supply voltage with large fluctuations and that is not suitable for electrical equipment within its set value range, so that various circuits or electrical equipment can work normally under the rated working voltage. Voltage stabilizers can be widely used in: industrial and mining enterprises, oil fields, railways, construction sites, schools, hospitals, post and telecommunications, hotels, scientific research departments, electronic computers, precision machine tools, computer tomography (CT), precision instruments, test equipment, elevator lighting, imported equipment and production lines, etc., which require stable power supply voltage. It is also suitable for users at the end of low-voltage distribution networks with low or high power supply voltage and large fluctuations, and electrical equipment with large load changes. It is especially suitable for all places with high requirements for power grid waveforms. High-power compensation power voltage stabilizers can be connected to thermal, hydraulic, and small generators.

2. Working principle of voltage stabilizer

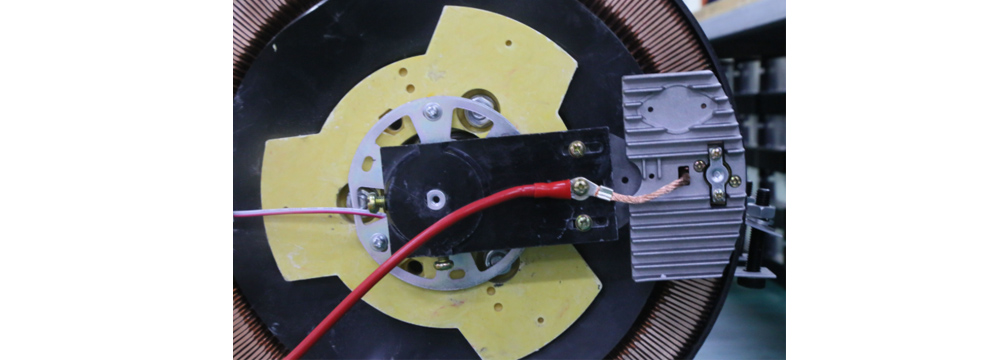

The power voltage stabilizer consists of voltage regulating circuit, control circuit, and servo motor. When the input voltage or load changes, the control circuit samples, compares, and amplifies, and then drives the servo motor to rotate, so that the position of the voltage regulator carbon brush changes, and the output voltage is kept stable by automatically adjusting the coil turns ratio. Larger capacity AC voltage stabilizers also work on the principle of voltage compensation.

3. Application areas of voltage stabilizers

Generally, there are two situations when the voltage of the power supply grid has problems:

A) The AC voltage is unstable, fluctuating, and fluctuates continuously.

B) The AC voltage is continuously low or high for a long time. Both of these situations are not conducive to the normal operation of electrical equipment, and serious electrical equipment may burn out.

There are generally three reasons for problems with the power supply voltage:

1) There are problems with the voltage stabilization device of the power plant generator, resulting in problems with the output voltage. This type is generally a small hydropower station.

2) There are problems with the performance of the power transformer in the substation or distribution station, especially those that are seriously dilapidated and aged.

3) The total power consumption in the area greatly exceeds the power supply load, resulting in a continuous low power supply voltage. In severe cases, the power supply frequency may be low, causing the power grid to be paralyzed and causing large-scale power outages!

Widely used: large-scale electromechanical equipment in the fields of industry, agriculture, transportation, post and telecommunications, military, railways, scientific research and culture, metal processing equipment, production lines, construction engineering equipment, elevators, medical equipment, embroidery and textile equipment, air conditioners, radio and television, household electricity, lighting and other power consumption occasions that require voltage stabilization.

4. The carbon brush in the voltage stabilizer is one of the key components. So, how often should the voltage stabilizer carbon brush be replaced?

We need to understand what a voltage stabilizer carbon brush is. A voltage stabilizer carbon brush refers to a device used to conduct current, often made of carbon material. The voltage stabilizer carbon brush is a key component connecting the voltage stabilizer and the motor. It mainly plays the role of conducting current and reducing motor sparks. The carbon brush is connected to the active part of the voltage stabilizer through a friction brush, thereby realizing the transmission of current. For the normal operation of the voltage stabilizer, the state of the carbon brush is crucial. So, how often do the carbon brushes of the voltage stabilizer need to be replaced?

The carbon brushes of the voltage stabilizer generally need to be replaced after one to two years of use. But the specific time depends on many factors such as the frequency of use, current load and working environment. It is recommended to check the wear of the carbon brushes every 6 months to 1 year. If severe wear or other abnormalities are found, they should be replaced in time.

4.1 Service life of carbon brushes

The service life of the voltage stabilizer carbon brushes is not fixed, but is affected by many factors. The first is the quality of the carbon brushes. If the voltage stabilizer carbon brushes themselves are of poor quality, the material is not strong, and they are easy to wear, then their life will be relatively short. Therefore, it is very important to choose high-quality carbon brush materials. The use environment is also one of the important factors affecting the life of the voltage stabilizer carbon brushes. If the voltage stabilizer is in a harsh environment such as humidity, high temperature, dust, etc. for a long time, the wear of the carbon brushes will increase and the consumption of the carbon brush life will be accelerated. Therefore, it is important to consider the installation environment of the voltage stabilizer and take protective measures. Generally speaking, under normal use, the life of the voltage stabilizer carbon brushes is about one to two years. However, if the voltage stabilizer needs to run for a long time every day, or the current load is large, the working environment is harsh, etc., the wear of the carbon brush will be accelerated, thus shortening its service life.

4.2 Factors affecting the service life of carbon brushes

4.2.1. Frequency of use: The more frequently the voltage stabilizer is used, the faster the carbon brushes will wear. Therefore, for voltage stabilizers that need to run for a long time, more attention should be paid to the status of the carbon brushes and the severely worn carbon brushes should be replaced in time.

4.2.2. Current load: The greater the current load, the greater the pressure on the carbon brushes during operation, and the wear rate will also be accelerated accordingly. Therefore, voltage stabilizers running under high load conditions need to check and replace carbon brushes more frequently.

4.2.3. Working environment: The temperature, humidity, dust, etc. in the working environment will affect the service life of the carbon brushes. A harsh working environment will accelerate the wear and aging of the carbon brushes. Therefore, in this case, more attention should be paid to the maintenance and replacement of the carbon brushes.

4.3 How to extend the service life of carbon brushes

In order to extend the service life of the voltage stabilizer carbon brushes, the following measures can be taken:

4.3.1. Regular maintenance inspection: It is recommended to conduct a comprehensive inspection of the voltage stabilizer every 6 months to 1 year, focusing on observing the wear of the carbon brushes. If severe wear or other abnormal phenomena are found, new carbon brushes should be replaced in time.

4.3.2. Maintain a good working environment: Try to keep the working environment of the voltage stabilizer clean, dry and well ventilated to reduce the impact of dust, humidity and other factors on the carbon brushes.

4.3.3. Choose high-quality carbon brushes: When purchasing a voltage stabilizer, you should choose products and accessories with reliable quality. High-quality carbon brushes have better wear resistance and conductivity, which can extend the service life and improve the overall performance of the voltage stabilizer.

The voltage stabilizer carbon brush is an important current conduction device. Its service life is closely related to factors such as carbon brush quality, use environment, and frequency of use. Under normal circumstances, it is a more appropriate choice to replace the voltage stabilizer carbon brush once every six months to one year. However, if an abnormal situation occurs, it needs to be replaced in time. Regular maintenance and inspection is also very important for the normal operation of the voltage stabilizer. Only by ensuring the normal operation of the voltage stabilizer carbon brushes can the voltage stability and safety of the voltage stabilizer be guaranteed.

Share our interesting knowledge and stories on social media