In industrial power systems, new energy vehicle charging piles, and medical equipment power supply scenarios, DC-DC converters, as core components for power conversion, not only need to achieve stable voltage regulation but also need to possess "self-protection capabilities" to cope with sudden situations such as short circuits and overloads. The instantaneous impact of abnormal current can cause minor damage to components or even paralyze the entire power supply system. The ability of a high-performance DC-DC converter to suppress abnormal currents depends not only on the design of the protection circuit but also on the precise implementation of multiple processes in the production process. From the calibration of the current detection circuit to the selection and matching of power protection devices, the control of every process detail is crucial for the DC-DC converter to achieve "rapid response and safe protection," which has become one of the core indicators distinguishing the quality of DC-DC converter products.

Current Detection Circuit: The Technological Foundation for "Sensing" Abnormal Current

(I) High-Precision Welding Process of Sampling Resistor

Current detection in a DC-DC converter relies on a sampling resistor to convert the current signal into a voltage signal. The welding quality directly affects the detection accuracy. Laser welding technology is used to weld 0.001Ω-0.01Ω alloy sampling resistors onto dedicated pads on the PCB. The welding temperature is controlled at 220℃±5℃, and the welding time is set to 0.8s-1.2s to ensure that the contact resistance of the solder joint is less than 5mΩ. After welding, the solder joint resistance is tested using a micro-ohmmeter. Products with a resistance deviation exceeding 10% are reworked to avoid current detection errors caused by excessive contact resistance and to ensure that the sampling signal can be accurately fed back to the control chip when abnormal current occurs.

(II) Parameter Calibration of the Detection Signal Amplification Circuit

The weak voltage signal (typically in the mV range) output by the sampling resistor needs to be amplified by an operational amplifier. The gain accuracy and temperature drift characteristics of the amplifier circuit need to be strictly calibrated. During production, a high-precision signal generator is used to simulate the sampling voltage corresponding to different currents, and the feedback resistor value of the amplifier is adjusted to control the gain error of the amplifier circuit within ±1%. Meanwhile, the circuit was placed in a temperature chamber ranging from -40℃ to 85℃ to test the amplifier's output deviation at different temperatures. By selecting an operational amplifier with low temperature drift (≤5μV/℃) and using a temperature compensation resistor, the detection signal deviation across the entire temperature range was ensured to be no more than 3%, providing a guarantee for accurate identification of abnormal currents.

Power Protection Devices: Key Processes for "Intercepting" Abnormal Currents

(I) Selection and Mounting Process of Resetting Fuses

Resetting fuses (PTCs) are crucial protection devices for DC-DC converters against overload currents. Their operating current and recovery time must match the product design. During the selection process, a PTC device with an operating current of 1.2 to 1.5 times the rated current should be selected based on the DC-DC converter's rated current (e.g., 5A, 10A), while ensuring that the device's operating current deviation does not exceed 8% at 85℃. During mounting, a high-precision pick-and-place machine is used to accurately position the PTC device on the designated location on the PCB. The mounting pressure is controlled between 5N and 8N to avoid poor heat dissipation due to mounting misalignment. This ensures that the PTC can quickly trip within 50ms and cut off the power circuit in the event of an overload current.

(II) Reverse Breakdown Voltage Calibration of TVS Diodes

Transient voltage suppressor diodes (TVS) are used to absorb transient high voltages caused by abnormal currents. Their reverse breakdown voltage (Vrwm) must match the bus voltage of the DC-DC converter. A high-voltage tester is used to perform reverse breakdown voltage tests on each TVS diode, and devices with a breakdown voltage deviation ≤5% are selected. For example, for a DC-DC converter with a bus voltage of 48V, a TVS device with a reverse breakdown voltage of 58V±2.9V should be selected. Simultaneously, the clamping voltage (Vc) and peak pulse current (Ipp) of the TVS were tested to ensure that under transient high voltage caused by abnormal current, the TVS can clamp the voltage within a safe range, protecting the subsequent circuitry from impact.

Control chip programming: the core technology for abnormal current "response".

(I) Precise Programming and Verification of Protection Logic

The control chip of the DC-DC converter (such as a PWM controller) needs to have abnormal current protection logic programmed into it, including parameters such as overcurrent threshold settings and delay protection time. An in-circuit programmer is used to program the protection program into the chip. After programming, different types of abnormal currents (such as short-circuit current and overload current) are simulated using a simulation test platform to verify the response speed of the protection logic. For example, the short-circuit current protection threshold is set to 3 times the rated current, requiring the control chip to shut off the PWM signal and cut off power output within 20μs. Through repeated testing 100 times, the success rate of the protection logic response is ensured to reach 100%, avoiding protection failure due to program vulnerabilities.

(II) Stability Calibration of Chip Power Supply Voltage

The stability of the control chip's power supply voltage directly affects the normal operation of the protection logic. A linear regulator (LDO) is needed to provide a stable 3.3V or 5V voltage to the chip. During production, a programmable DC power supply is used to simulate different input voltages (e.g., 9V-36V) to test the output voltage deviation of the LDO. The feedback resistor of the LDO is adjusted to control the output voltage deviation within ±2%. Simultaneously, the output ripple of the LDO is tested under varying load current (e.g., 10mA-100mA) to ensure the peak-to-peak ripple does not exceed 50mV, providing a stable power supply for the control chip and ensuring reliable triggering of the abnormal current protection logic.

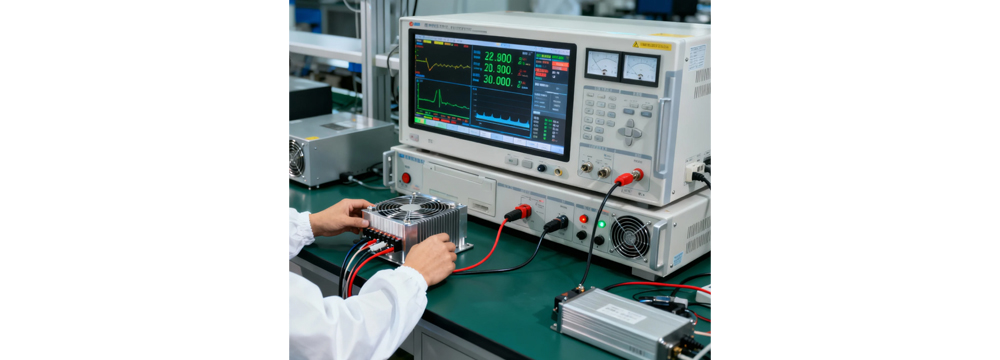

IDEALPLUSING's Abnormal Current Suppression Process Practice

In the field of DC-DC converter manufacturing, IDEALPLUSING has established a "triple verification" system for its abnormal current suppression process: First, the accuracy of the current detection circuit is tested 100% using automated testing equipment; second, the stability of the power protection device is verified through high and low temperature cycling tests; and finally, more than 10 abnormal current scenarios are simulated using a simulation platform to verify the response effect of the protection logic. For example, in the production of a certain 24V/10A DC-DC converter, its abnormal current protection response time can be stably controlled within 15μs, and the overload protection operation error does not exceed 5%, fully meeting the stringent power supply safety requirements of industrial equipment.

Conclusion

The ability of a DC-DC converter to suppress abnormal current is the result of coordinated efforts across the entire "sensing-interception-response" chain in the manufacturing process—from the laser welding of the sampling resistor to the programming of the control chip, the precision control of each process determines the product's safety performance under sudden conditions. For users, choosing a reliable DC-DC converter is not only about choosing stable power conversion capabilities, but also about choosing a safety protection system that has undergone rigorous process verification. IDEALPLUSING, through continuous optimization of abnormal current suppression technology, is providing global users with DC-DC converter solutions that combine high-efficiency conversion and safety protection, driving the upgrade of safety standards in the power supply equipment field.

Share our interesting knowledge and stories on social media