In the entire process of industrial production, equipment research and development, and testing, power supply equipment consistently plays the role of an "energy cornerstone." Programmable DC power supplies, with their flexible control and precise output characteristics, have become indispensable key equipment in modern industrial settings. From automated production lines to precision electronic testing, the application of programmable DC power supplies profoundly impacts the efficiency of industrial production, product quality, and technological innovation. Their diverse functions and reliable performance are reshaping the energy supply model in the industrial sector.

Stable Supply in Industrial Production

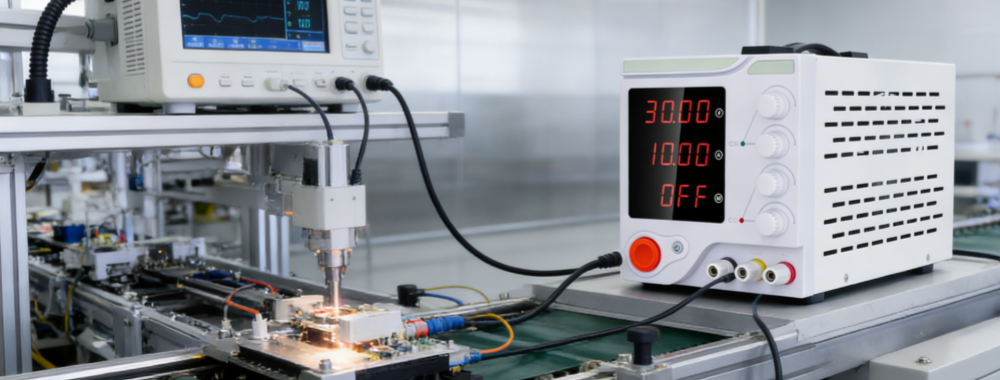

Various equipment on industrial production lines have extremely high requirements for power supply stability. Voltage fluctuations or current instability can lead to production interruptions, product defects, and other serious consequences. Programmable DC power supplies can precisely set output voltage and current parameters according to the real-time needs of production equipment, and maintain output stability through intelligent control technology, ensuring balanced energy supply even under load changes. Whether it's motor drives in automotive parts processing or power supply for welding equipment during electronic component assembly, programmable DC power supplies provide continuous and stable energy support, reducing production stoppages caused by power supply problems and safeguarding the continuity of industrial production. It's worth noting that IDEALPLUSING's programmable DC power supplies have gained recognition from many companies for their anti-interference capabilities in complex industrial environments.

Precise Assistance in Equipment Research and Development and Testing

In the industrial equipment research and development and performance testing stages, the flexible programmability of programmable DC power supplies plays a crucial role. R&D personnel can freely set the power supply's output mode and change curves through software programming, simulating power supply conditions under different working conditions, thereby comprehensively testing the equipment's operating performance under various energy conditions. For example, in the development of new energy vehicle charging piles, programmable DC power supplies can simulate different stages of battery charging, precisely testing the charging efficiency and compatibility of the charging pile; in industrial sensor testing, they can provide various output modes such as step and pulse, helping R&D personnel quickly identify equipment performance bottlenecks. The precise control capabilities of programmable DC power supplies significantly shorten the R&D cycle of industrial equipment, reduce testing costs, and provide strong support for technological innovation.

Energy Saving, Environmental Protection, and Intelligent Upgrading

As the industrial sector transforms towards green, low-carbon, and intelligent development, the energy-saving and environmentally friendly characteristics of programmable DC power supplies are becoming increasingly prominent. Their high energy conversion efficiency reduces energy loss and lowers energy consumption costs in industrial production, aligning with the development concept of low-carbon industry. Meanwhile, programmable DC power supplies support remote control, data acquisition, and analysis functions, and can seamlessly integrate with industrial Internet of Things (IoT) systems, enabling real-time monitoring and centralized management of power supply operating status. This intelligent feature not only simplifies industrial energy management processes but also optimizes power usage strategies through data analysis, further improving the overall energy efficiency of industrial systems and assisting enterprises in achieving intelligent upgrades.

The application of programmable DC power supplies has permeated various critical aspects of industrial production. Their advantages of stable supply, precise control, and energy efficiency are becoming an important guarantee for high-quality industrial development. Against the backdrop of continuous technological advancements, programmable DC power supplies will continue to iterate and upgrade, injecting stronger energy and momentum into the innovative development of the industrial sector.

IDEALPLUISNG Power Expert:

We focus on the research and development, sales and services in the fields of DC-DC power modules, AC-DC rectifier modules, DC-AC inverters, AC power supplies, DC power supplies, LED power supplies, chargers, rectifier systems, etc., providing personalized, efficient, reliable and cost-effective power solutions for all walks of life.

Thank you for considering our services.