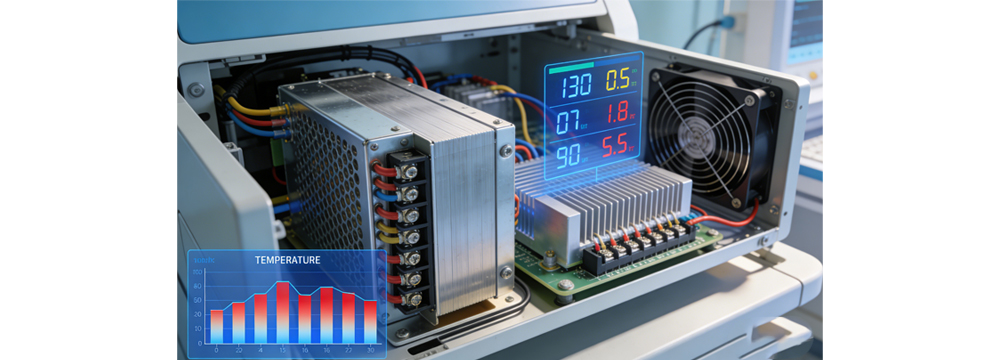

As the core power unit of power electronic equipment, the stable operation of HV Power supplies directly depends on the performance of the thermal management system. Thermal simulation technology breaks the limitations of traditional thermal management design relying on experience through precise modeling and data simulation. With this technology, engineers can predict thermal bottlenecks in advance, tailor efficient thermal management solutions for HV Power supplies, and significantly improve product reliability and service life.

1. Core Pain Points in Thermal Management Design of HV Power Supplies

During the operation of HV Power supplies, core components such as power semiconductor devices and transformers generate a large amount of heat. Due to their compact internal structure and high voltage level, heat is prone to accumulate. Traditional thermal management design mostly relies on engineers' experience in component selection, which often leads to mismatches between the thermal management solution and actual heat generation: either excessive heat dissipation results in cost waste, or insufficient heat dissipation causes the equipment to operate in a high-temperature environment for a long time, triggering faults such as insulation aging and component parameter drift.

More importantly, the heat distribution of HV Power supplies is significantly uneven, and the temperature of local hotspots is often much higher than the average temperature. This problem is particularly prominent in high-power, compact HV Power supplies. Traditional experimental testing methods are difficult to fully capture temperature changes under dynamic working conditions, and the testing cycle is long and costly, which cannot meet the needs of rapid product iteration. These pain points make the thermal management design of HV Power supplies a key bottleneck restricting product performance improvement.

2. Working Principle and Advantages of Thermal Simulation Technology

Based on computational fluid dynamics (CFD) and heat transfer theory, thermal simulation technology conducts numerical simulation of the temperature field and flow field inside the HV Power supply by establishing a three-dimensional thermodynamic model. Engineers can input structural parameters, material thermal conductivity, power loss data of the HV Power supply into simulation software to accurately simulate the process of heat generation, conduction, convection and radiation under different working conditions.

Compared with traditional design methods, thermal simulation technology has three core advantages: first, strong forward-looking, which can complete the verification of thermal management solutions before product prototype production, avoiding cost increases caused by later modifications; second, high accuracy, which can clearly show the location and temperature peak of local hotspots, providing data support for targeted optimization; third, high flexibility, which can quickly switch thermal management solutions, adjust structural parameters, simulate the impact of different external conditions such as ambient temperature and wind speed on thermal management effects, and greatly shorten the design cycle.

3. Practical Application of Thermal Simulation in HV Power Supply Thermal Management Design

In the thermal management design of HV Power supplies, thermal simulation technology is applied throughout the entire product R&D process. In the scheme design stage, engineers can compare the effects of different thermal management methods such as natural cooling, forced air cooling, and liquid cooling through simulation, and select the optimal scheme according to the product application scenario. For example, for industrial-grade HV Power supplies, simulation shows that increasing the tilt angle of cooling fins can improve air circulation efficiency, increasing thermal management effect by more than 15%.

In terms of structural optimization, thermal simulation can guide the layout design of core heating components. By adjusting the installation position of power devices and radiators, and optimizing the shape and size of heat dissipation channels, the temperature of local hotspots can be effectively reduced. A medical equipment HV Power supply adjusted the distance between the transformer and IGBT devices through thermal simulation and optimized the heat dissipation air duct, reducing the maximum temperature of the equipment by 22℃ and improving stability by 30%.

In addition, thermal simulation can also be used for the selection and optimization of thermal management materials. By simulating the heat transfer effect of different thermal conductive silicone greases and heat dissipation substrates, the balance between cost and performance can be achieved under the premise of meeting thermal management requirements. For special application environments such as high altitude and high temperature, thermal simulation can predict the thermal management performance under extreme conditions in advance, ensuring the stable operation of HV Power supplies in complex environments.

4. Future Development Trends of Thermal Simulation Technology

With the development of HV Power supplies towards high power density and miniaturization, thermal simulation technology is constantly upgrading and iterating. In the future, thermal simulation will be deeply integrated with multi-physics simulation to realize multi-field coupling simulation such as electro-thermal and electromagnetic-thermal, which can more comprehensively reflect the working state of HV Power supplies. The integration of AI algorithms will further improve simulation efficiency, and quickly optimize thermal management solutions through machine learning, reducing manual intervention.

At the same time, thermal simulation technology will develop towards refinement and intelligence, which can simulate more complex thermal management structures and material properties, and even realize the combination of real-time simulation and online monitoring. This means that during the operation of HV Power supplies, the thermal management strategy can be adjusted through real-time data feedback to achieve dynamic thermal management optimization, providing comprehensive protection for the stable operation of HV Power supplies.

5. Conclusion

Thermal simulation technology, with its precise, efficient and forward-looking characteristics, is reshaping the thermal management design mode of HV Power supplies. It not only solves the problems of experience dependence, high cost and low efficiency in traditional design, but also promotes the development of HV Power supplies towards high reliability, high power density and low cost. Against the background of the rapid development of the power electronics industry, thermal simulation technology will become a key support for HV Power supply enterprises to enhance their core competitiveness, providing comprehensive protection for the stable operation of more high-end power electronic equipment.

Share our interesting knowledge and stories on social media