Introduction

Reasonable selection criteria for high-voltage capacitors are the core guarantee for the stable operation of HV Power Supply, directly determining the anti-interference ability and service life of the power supply system; neglecting key parameter matching will lead to frequent power supply failures, thereby affecting the overall operating efficiency of downstream power electronic equipment.

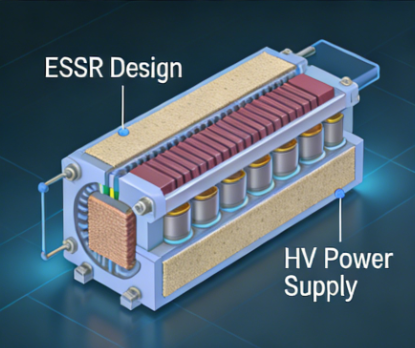

1. Core Position of High-Voltage Capacitors in HV Power Supply

In the field of power electronics, HV Power Supply (High-Voltage Power Supply) is the core power unit for equipment such as radar, medical imaging, and industrial coating. As a key passive component, high-voltage capacitors undertake core functions such as energy storage, filtering and noise reduction, and voltage division. Different from ordinary low-voltage capacitors, capacitors in high-voltage scenarios need to withstand kilovolt-level or even higher voltage impacts, and their performance stability is directly related to the output accuracy and operational safety of HV Power Supply. For example, in high-frequency and high-voltage power supplies, the charge and discharge speed of capacitors affects the response efficiency of the power supply; in high-voltage filter circuits, the capacitance stability of capacitors determines the ripple coefficient of the output voltage. Therefore, high-voltage capacitors are by no means simple "energy containers", but "invisible cornerstones" of HV Power Supply reliability.

2. Three Core Parameters Easily Overlooked in Selection

(1) Matching Between Voltage Level and Dielectric Loss

Most selectors only pay attention to whether the rated voltage of the capacitor is higher than the working voltage, but ignore the collaborative relationship between dielectric loss (tanδ) and voltage level. During the long-term operation of HV Power Supply, excessive dielectric loss will cause serious heating of the capacitor, thereby accelerating insulation aging and ultimately leading to breakdown failure. High-quality high-voltage capacitors should use low-loss dielectrics such as polypropylene and polytetrafluoroethylene, with a rated voltage reserved for a safety margin of more than 30%, and ensure that the dielectric loss tangent value at the rated voltage is less than 0.001. Although this selection standard seems strict, it can effectively avoid capacitor failure of HV Power Supply when voltage fluctuates.

(2) Frequency Characteristics and Environmental Adaptability Design

The operating frequency range of high-voltage power supplies varies greatly, from power frequency to MHz-level high frequency, and the capacitance of capacitors will shift with frequency changes. In high-frequency HV Power Supply, if ordinary power frequency capacitors are used, the filtering effect will decrease due to capacitance attenuation, and the power supply output ripple will exceed the standard. In addition, temperature and humidity fluctuations in industrial scenarios will also affect capacitor performance. Therefore, products with a temperature resistance range of -40℃~125℃ and a moisture-proof sealed structure should be selected. For example, in outdoor high-voltage power supply equipment, high-voltage capacitors packaged in ceramic casings have much better anti-environmental interference ability than plastic-packaged products, which can effectively extend the outdoor service life of HV Power Supply.

(3) Hidden Impact of Equivalent Series Resistance (ESR)

Equivalent Series Resistance (ESR) is a key parameter of high-voltage capacitors, but it is often overlooked by selectors. Excessively high ESR will cause additional power consumption of the capacitor during charge and discharge, which not only reduces the energy conversion efficiency of HV Power Supply, but also accelerates capacitor aging due to heating. In high-voltage pulse power supplies, capacitors with low ESR can release energy faster to ensure that the peak voltage of pulse output meets the standard; while products with high ESR will cause pulse waveform distortion, affecting the working accuracy of the power supply. Therefore, when selecting HV Power Supply, priority should be given to high-voltage capacitors with an ESR value lower than 50mΩ, especially in high-frequency and high-current scenarios, the control of ESR is more critical.

3. Power Supply Reliability Hazards Caused by Selection Deviations

In practical applications, cases of HV Power Supply failures caused by improper selection are common. A certain industrial coating equipment's HV Power Supply frequently shut down. After investigation, it was found that ordinary high-voltage ceramic capacitors were used, whose excessive dielectric loss led to internal heating and capacitor breakdown after long-term operation. After replacing with low-loss polytetrafluoroethylene dielectric capacitors, the equipment operated continuously for 3000 hours without failure. In another case, a medical high-voltage power supply used capacitors without temperature compensation function, and the capacitance drift exceeded 10% when the ambient temperature changed, leading to distortion of the imaging equipment's screen. These cases show that the selection criteria of high-voltage capacitors directly determine the failure rate of HV Power Supply, thereby affecting the operational stability of the entire power electronic system.

4. Practical Suggestions for Scientific Selection

(1) Establish a Parameter Linkage Evaluation System

During selection, single-parameter consideration should be avoided, and a linkage evaluation model for parameters such as voltage, frequency, ESR, and dielectric loss should be established. For example, in high-frequency HV Power Supply, priority should be given to ensuring low ESR and wide frequency adaptability; in high-voltage DC power supply, the focus is on voltage margin and dielectric loss. At the same time, combined with the working mode of HV Power Supply (continuous operation or pulse operation), select the corresponding capacitor type—metalized polypropylene capacitors are suitable for continuous operation scenarios, and ceramic capacitors are preferred for pulse scenarios.

(2) Attach Importance to Manufacturers' Reliability Test Data

High-quality high-voltage capacitor manufacturers will provide detailed reliability test reports, including high-temperature aging test, voltage impact test, life cycle test and other data. When selecting, priority should be given to products certified by IEC 60384-1 standard and with a capacity attenuation rate of less than 5% in aging tests. In addition, the manufacturer's production process is also crucial. Capacitors using vacuum coating technology have stronger electrode adhesion and better stability in high-voltage environments than traditional spraying process products.

(3) Conduct Trial-and-Error Verification in Combination with Actual Scenarios

Even if the parameters match, the actual performance of capacitors from different brands may vary. Therefore, before mass application, 3-5 candidate products should be selected for actual working condition testing to monitor their temperature change, capacitance stability, ESR fluctuation and other indicators in HV Power Supply. Through continuous operation testing for more than 1000 hours, the most suitable high-voltage capacitor for the target scenario is selected to ensure the reliability of the power supply from the source.

Conclusion

Although the selection criteria for high-voltage capacitors seem cumbersome, they are actually the core guarantee for the reliability of HV Power Supply. With the continuous upgrading of power electronic technology, neglecting selection details will lead to frequent power supply failures, thereby increasing operation and maintenance costs. Only by establishing a scientific selection system, attaching importance to parameter matching, manufacturer qualifications and actual verification, can high-voltage capacitors truly play the role of "stabilizer" and promote the safe and efficient operation of HV Power Supply in various industries.

Share our interesting knowledge and stories on social media