Have you ever wondered: how does the battery in an energy vehicle make the voltage work with the little things in the car that need 12 volts? Like the radio and the lights. How do they take the voltage direct current, in the big control cabinets at work and turn it into the low voltage that the sensors need to work right?. Have you ever thought about how a power bank that you use to charge your phone can always give a steady 5 volts of power to charge your mobile phone?

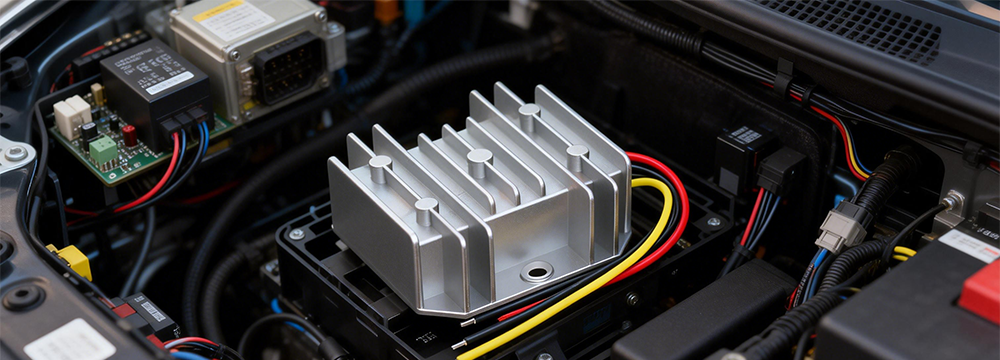

The answer lies in the inconspicuous yet crucial DC-DC converter .

Simply put, the core task of a DC-DC converter is to act as a "voltage transformation magician" for DC power – precisely converting DC power of one voltage level into another or multiple voltages, while simultaneously achieving voltage stabilization, isolation, and efficient transmission. It can be found everywhere, from consumer electronics to industrial control, from automotive systems to new energy power generation.

So, what makes DC-DC converters so "versatile"? We can start with three core advantages:

1. Strong adaptability, covering all voltage requirements: Whether it's a "step-down" scenario (such as reducing a 48V industrial power supply to 5V to power a microcontroller), or a "step-up" application (such as increasing a 3.7V lithium battery voltage to 12V to power an LED light), or even precision instrument scenarios requiring positive and negative voltage outputs, DC-DC converters can achieve this through different topological structures. Non-isolated topologies (such as Buck, Boost) are small in size and highly efficient, suitable for consumer electronics and small appliances; isolated topologies (such as Flyback, Forward) offer high safety, isolating high and low voltage interference, making them more suitable for demanding scenarios such as industrial control and automotive applications.

2. High efficiency, saving power means saving money: For high-power applications such as industrial equipment and new energy vehicles, the efficiency of the converter directly affects energy consumption and operating costs. High-quality DC-DC converters can achieve efficiencies of over 90%, significantly reducing energy loss compared to traditional linear voltage regulators, thus reducing equipment heating problems and saving on long-term electricity costs.

3. Good stability, protecting the "lifeline" of equipment: In industrial scenarios, power grid voltage fluctuations and sudden load changes are common occurrences. DC-DC converters come with built-in voltage regulation, filtering, and overcurrent protection functions, ensuring a stable output voltage and preventing damage to precision sensors, controllers, and other core components due to voltage fluctuations. They are, in essence, the "invisible guardians" of stable equipment operation.

Of course, choosing and using DC-DC converters correctly requires avoiding some common misconceptions: for example, blindly pursuing high power without considering size limitations, or confusing the applicable scenarios of isolated and non-isolated topologies.We are going to share tips about how to select and use things in the future. This will help you find the things that're right for your needs. We want to help you make choices that are just right, for you and the things you need.

In short, DC-DC converters may not have a flashy appearance, but their powerful adaptability, high efficiency, and stability have made them indispensable core components in the field of power electronics.

Share our interesting knowledge and stories on social media