In fields such as industrial control, automotive electronics, and new energy, DC-DC converter often need to operate stably under harsh conditions like high temperature, high humidity, strong vibration, and electromagnetic interference. The rationality of their selection directly determines the overall reliability and service life of the equipment. In many engineering cases, equipment downtime and frequent failures caused by inadequate adaptability of converters not only increase maintenance costs but also may lead to potential safety hazards. Combining the core characteristics of harsh operating conditions, this article analyzes the selection logic and optimization techniques of DC-DC converters.

I. First, Clarify the Core Challenges of Harsh Operating Conditions

Harsh operating conditions vary in different scenarios, but the core challenges focus on three categories: first, environmental stress, such as high temperature in industrial workshops (-40℃~85℃ or even higher), temperature and humidity alternation of outdoor equipment, and severe vibration in automotive scenarios; second, electrical interference, such as strong electromagnetic radiation in industrial sites and voltage shocks caused by power grid fluctuations; third, load fluctuations, such as instantaneous heavy loads of construction machinery and pulse loads of new energy equipment. Before selection, it is necessary to accurately identify scenario pain points and avoid "one-size-fits-all" selection of general-purpose products.

II. Core Selection Points: Starting from Tolerance Capacity

1. Temperature and Humidity Adaptation: Breaking Through Environmental Limits

High temperature is the most common fatal factor in harsh operating conditions, so priority should be given to the operating temperature range of the converter. Regular converters you buy are good for temperatures, between 0℃ and 60℃.. If things get really tough you need special converters that can handle very cold and very hot temperatures like -40℃ to 85℃. You also have to check how the product works when it is very cold or very hot to make sure it still works well and gives you the results. The converters need to be able to handle these temperatures without losing a lot of accuracy and efficiency. When we are dealing with humidity and salt spray like in marine engineering and outdoor solar panels we need to choose products that can really withstand these conditions. For these situations we should pick products that have a protection level of IP65 or higher. These products should also have anti-corrosion coatings to keep moisture and salt from causing damage. This way we can keep the moisture and salt from getting in and causing problems. We need to select products, with IP65 or above protection level and anti-corrosion coatings for engineering and outdoor solar panels.

2. Anti-Interference and Stability: Resisting Electrical Shocks

When we are talking about Electromagnetic Interference or EMI in sites it can really mess with the control chip of the converter. This can cause the output to fluctuate over the place.

So when you are picking out a product make sure to check the Electromagnetic Compatibility or EMC certifications, like the ones that say EN55032 or CISPR 22.

It is also an idea to prioritize the models that have input surge suppression and really low output ripple I mean we are talking one percent or less. This will help with the Electromagnetic Interference issue. When we are talking about things like cars and power equipment we have to deal with changes in voltage. So we need to look at the voltage range that the converter can handle. It is an idea to add a little extra room, about twenty percent more just in case. The converter should also have some protection features, like protection from much voltage too much current and short circuits. This way if something goes wrong with the electricity the converter can handle it. We need to make sure the voltage converter has these protection features so it can deal with electrical problems. The voltage converter should be able to handle overvoltage, overcurrent and short-circuit protection which's very important for things, like cars and power equipment.

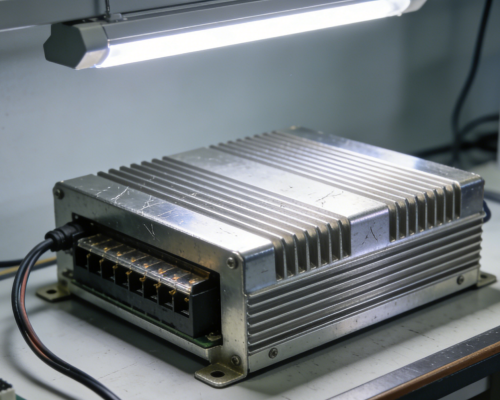

3. Mechanical Strength: Adapting to Vibration and Impact

In scenarios with frequent vibrations such as rail transit and construction machinery, the mechanical structure of the converter is crucial. Choose products with reinforced casings and anti-vibration pin designs, confirm their vibration resistance level (such as IEC 60068-2-6 standard), and avoid solder joint detachment and component loosening caused by long-term vibration. In addition, modular converters are easier to maintain, reducing maintenance difficulty in harsh environments.

III. Post-Selection Optimization: Further Improving Reliability

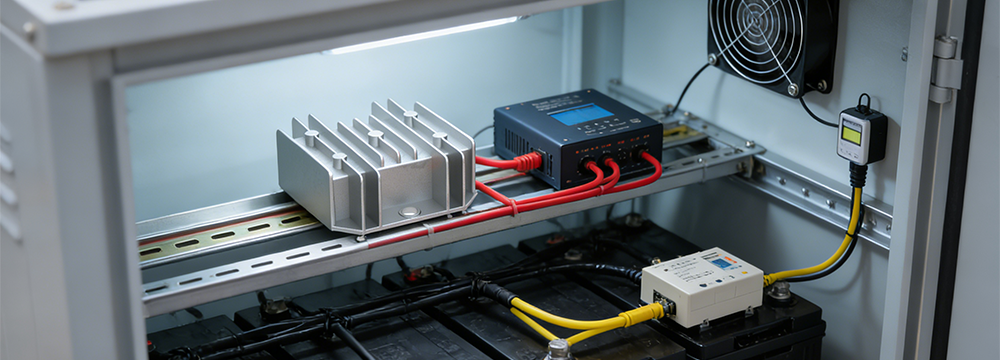

Selection is not the end; targeted optimization can further extend the service life of the converter.At the electrical level, filters and fuses should be installed at the input to mitigate grid interference and prevent overloads.To optimize thermal management, utilized are heat pads and sinks—components that enhance heat conduction and prevent prolonged high-temperature accumulation within the converter. When necessary, activated may be temperature-controlled fans to deliver active cooling.

Furthermore, attention must be paid to installation specifics: near high-power heat sources shall the converter never be placed, and sufficient clearance for airflow must be ensured. For vibration-prone environments, shock-absorbing brackets should be adopted for mounting, so as to mitigate mechanical stress on the device.

In the course of routine inspections, priority should be given to monitoring two critical metrics: the converter’s output accuracy and temperature rise. Only by doing so can potential faults be detected at an early stage.

IV. Summary: The Core of Selection is "Precise Matching"

The core of selecting DC-DC converters for harsh operating conditions is to achieve precise matching between product performance and scenario challenges—neither blindly pursuing high parameters to cause cost waste nor sacrificing reliability due to insufficient parameters. It is recommended to first sort out the core indicators of the scenario such as temperature, vibration, and electromagnetic interference, then select dedicated models with wide temperature range, anti-interference, and anti-vibration capabilities accordingly, and combine them with post-optimization measures to achieve stable operation of the converter under harsh conditions and lay a solid foundation for the overall reliability of the equipment.

We at IDEALPLUSING not only provide products, but also strive to provide customers with suitable power supply solutions and quotations.

Our core competitiveness lies in carefully selecting a variety of power supply options to help customers evaluate and choose the most suitable power supply solution.

We can offer AC DC power supply, DC AC inverter, AC AC power source(single phase or 3 phases),AC DC Ground Power Unit...

Share our interesting knowledge and stories on social media