In complex application scenarios such as industrial automation, rail transit, and medical equipment, DC-DC converters serve as the core hub for power conversion, acting as the "energy heart" that ensures the stable operation of terminal equipment. Unlike the consumer electronics field, industrial environments are generally characterized by severe voltage fluctuations, extreme temperature and humidity ranges, and dense electromagnetic interference, imposing much stricter requirements on the performance indicators of converters than ordinary scenarios. Their core technical requirements focus on three key dimensions: high efficiency and energy saving, reliability and durability, and flexible adaptability, collectively building a stable defense line for industrial power supply systems.

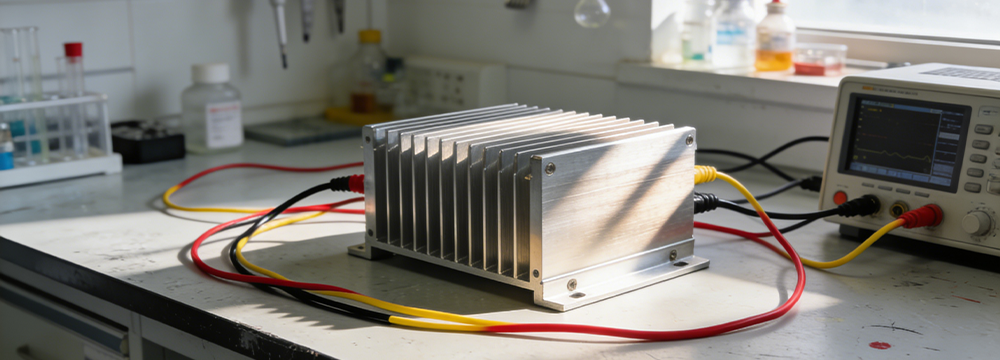

High conversion efficiency is the primary technical requirement for industrial-grade DC-DC converters. Most industrial equipment needs to operate continuously 24 hours a day; energy loss caused by low-efficiency conversion not only increases operating costs but also leads to excessive module temperature rise, accelerating the aging and failure of internal components. High-efficiency energy conversion can be achieved through topology optimization and upgrading of core component selection. For example, the LLC resonant topology significantly reduces switching losses by virtue of its soft-switching characteristics, and the synchronous rectification technology replacing the traditional diode rectification scheme can increase the full-load conversion efficiency of the module to over 93%. High conversion efficiency enables the module to operate stably through natural heat dissipation without relying on forced air cooling, which not only simplifies the overall system structure but also reduces the failure risk of heat dissipation components, making it particularly suitable for enclosed scenarios such as sealed industrial control cabinets.

Adaptability to extreme environments is the core embodiment of reliability requirements. Industrial sites often face wide temperature range challenges from -40℃ low temperature to 105℃ high temperature. Converters need to ensure that key parameter drift is controlled within the allowable range through the collaborative design of full potting process, high thermal conductivity substrates, and temperature compensation circuits. At the same time, industrial power grids have frequent voltage fluctuations, so converters must have an ultra-wide input range of 18V-75V, be compatible with 24V/48V mainstream industrial bus standards, and cope with voltage transients and surge impacts calmly. In addition, a high isolation voltage design of 3000VDC and above is indispensable, which can effectively block ground loop interference and meet the safety standards of scenarios with high electrical safety requirements such as railway signals and medical equipment.

Multiple protection mechanisms and long-term stable operation capabilities are another important support for reliability requirements. Sudden shutdown of industrial equipment may cause serious consequences such as production line interruption and loss of core data. Therefore, converters must be equipped with full-dimensional protection mechanisms such as overvoltage, overcurrent, overtemperature, and short circuit, which can quickly turn off the output and achieve automatic recovery in the event of a fault, minimizing losses. By improving the Mean Time Between Failures (MTBF) through means such as circuit topology optimization and component screening and upgrading, mainstream industrial-grade modules can achieve stable operation of more than 2.5×10⁶ hours. Meanwhile, passing rigorous vibration and shock tests, they can resist the continuous mechanical stress impacts in scenarios such as rail transit and heavy machinery.

Flexible adaptability and precise control capabilities are designed to meet the diverse load requirements of industrial scenarios. Industrial load types are complex; converters need to support constant voltage/constant current dual-mode output and have a wide-range voltage regulation function, which can adapt to loads with different characteristics such as capacitive, inductive, and resistive without complex peripheral circuits. For equipment with high requirements for power supply quality such as PLCs and precision sensors, the output ripple must be strictly controlled within 100mVp-p, and the load step response time must be shortened to less than 50μs to ensure the accuracy of analog signal acquisition and the stable operation of digital circuits. In addition, the design of small size and high power density is crucial. The 1/8 brick package module can achieve 240W power output in a limited installation space, perfectly adapting to the development trend of integration and miniaturization of industrial equipment.

Electromagnetic Compatibility (EMC) is an essential technical requirement for industrial-grade converters. Equipment such as frequency converters and high-power motors in industrial sites generate a lot of electromagnetic interference. Converters need to strictly comply with the IEC 61000 series of electromagnetic compatibility standards through means such as EMI suppression circuit optimization and all-metal shielding design, which not only prevents themselves from becoming electromagnetic interference sources affecting surrounding equipment but also resists the invasion of external pulse interference and radiation interference. For special scenarios such as medical equipment, low leakage current design must be strengthened to ensure human safety while guaranteeing stable power supply.

In summary, the technical requirements of industrial-grade DC-DC converters are constantly iterating and upgrading around the harshness and diversity of industrial scenarios. The core technical characteristics of high efficiency, reliability, and flexibility empower and support each other, which are not only the core embodiment of the converter's own performance competitiveness but also an important cornerstone for ensuring the continuous, stable, and safe operation of the entire industrial system, providing solid energy guarantee for the development of industrial automation towards higher precision, higher efficiency, and higher reliability.

We at IDEALPLUSING not only provide products, but also strive to provide customers with suitable power supply solutions and quotations.

Our core competitiveness lies in carefully selecting a variety of power supply options to help customers evaluate and choose the most suitable power supply solution.

We can offer AC DC power supply, DC AC inverter, AC AC power source(single phase or 3 phases),AC DC Ground Power Unit...

Share our interesting knowledge and stories on social media