DC-DC converters are core power supply parts in industrial equipment. They turn input DC voltage into stable output that works for loads like microcontrollers, sensors and actuators. Industrial environments are full of strong electromagnetic interference (EMI) and abnormal operating conditions. So, anti-interference ability and reliable protection systems are vital to keep equipment running non-stop and extend its service life. This article looks at the main anti-interference techniques and protection mechanisms of DC-DC converters in industrial use.

1. Anti-Interference Technologies for DC-DC Converters

Industrial sites have many EMI sources, such as motor commutation, high-voltage switching operations and radio frequency signals. EMI spreads through conduction or radiation, leading to voltage fluctuations, output ripples and even converter breakdowns. It’s thus necessary to take targeted anti-interference steps.

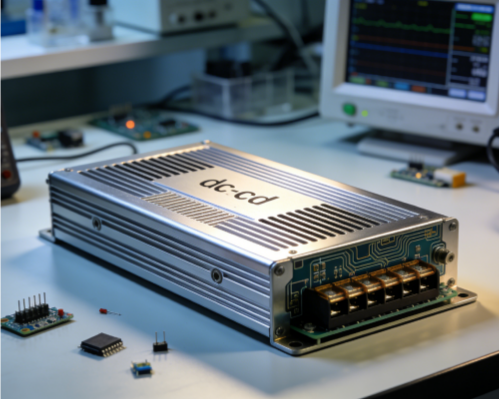

First, electromagnetic shielding is a key method to resist radiated interference. Converters use metal casings with good conductivity to absorb and reflect electromagnetic waves. This stops external EMI from getting into internal circuits and prevents the converter itself from disturbing nearby equipment. The shielding case must be properly grounded to remove accumulated charges and boost shielding performance.

Second, filtering technology curbs conducted interference. Converters’ input and output ends are fitted with LC filters or π-type filters, which weaken high-frequency interference signals in power lines. Ferrite beads are also used in wiring to reduce common-mode and differential-mode interference, ensuring steady input voltage and clean output waveform. For sensitive industrial equipment, isolated converters are better choices. Their isolation transformers block common-mode interference’s conduction paths, greatly enhancing anti-interference ability.

2. Protection Mechanisms of DC-DC Converters

Industrial equipment frequently encounters abnormal operating conditions such as overvoltage, overcurrent and overtemperature, all of which may harm DC-DC converters and the loads connected to them. To respond promptly to faults and guarantee system security, DC-DC converters are equipped with a variety of protective mechanisms.

Overcurrent protection (OCP) ranks among the most fundamental protective features. It keeps track of output current in real time. When the current surpasses a preset threshold—caused by load short circuits or overloads—the converter activates protective measures by restricting current output or switching off the switching tube. Foldback current limiting is widely adopted in industrial converters; it reduces the current threshold as voltage declines, preventing excessive power dissipation during fault conditions.

Overvoltage protection (OVP) and undervoltage lockout (UVLO) defend against voltage irregularities. The OVP keeps an eye on the output voltage. If something goes wrong with the feedback circuit, which's really important for controlling the voltage and it gets too high or too low the converter will turn off right away to keep the sensitive equipment safe. The UVLO makes sure the converter only starts working when the input voltage's just right. It does this by letting the converter start when the input voltage is, within the correct range. This helps prevent the converter from working or getting damaged because the input voltage is not good enough. The OVP and UVLO work together to protect the converter. The equipment it is connected to.

Overtemperature protection (OTP) tackles heat-related issues in severe industrial environments. In factories and other industrial places it can get really hot. The machines have to work very hard for a long time. This makes a lot of heat in the converters. To keep an eye on how hot it gets converters have temperature sensors inside them like thermistors that can feel even tiny changes, in temperature. These sensors check the temperature levels of the converters all the time. Once the critical temperature is breached, the converter will either reduce output power or shut down until it cools to a safe degree, thereby warding off thermal failure of switching tubes and capacitors.

Overcurrent protection (OCP) is one of the most basic protection functions. It monitors output current in real time. When the current goes beyond a preset limit—due to load short circuits or overloads—the converter activates protection by limiting current output or turning off the switching tube. Foldback current limiting is commonly used in industrial converters. It lowers the current limit as voltage drops, avoiding too much power loss during faults.

3. Application Practice

In industrial automation, power grids and heavy machinery, DC-DC converters with strong anti-interference and protection abilities keep equipment running stably in harsh conditions. For instance, in factory automation systems, isolated converters with shielding and multi-level filtering resist EMI from frequency converters and motors. Meanwhile, overcurrent and overtemperature protection stops faults from spreading to the whole control system.

In short, anti-interference technologies and protection mechanisms are key to DC-DC converters’ reliability in industrial applications. The industrial Internet of Things and smart manufacturing are getting better. This means converters will be able to work more smoothly. They will also be able to stop interference and protect things accurately. When we make these technologies better they will help keep equipment running well and working properly. This is important, for the Industry 4.0 revolution. Industry 4.0 is a change and it needs a strong base to work properly.

DC-DC converters are important parts of the power supply in industrial equipment. They help convert the input DC voltage into an output that is good for things like microcontrollers and sensors and actuators. Industrial environments can be very tough on equipment because of interference and weird working conditions. This means that DC-DC converters need to be able to deal with interference and have protection mechanisms to keep the equipment running smoothly and to make it last longer. This paper is about the ways that DC-DC converters can handle interference and the protection mechanisms they use in industrial applications specifically, for DC-DC converters.

We at IDEALPLUSING not only provide products, but also strive to provide customers with suitable power supply solutions and quotations.

Our core competitiveness lies in carefully selecting a variety of power supply options to help customers evaluate and choose the most suitable power supply solution.

We can offer AC DC power supply, DC AC inverter, AC AC power source(single phase or 3 phases),AC DC Ground Power Unit...

Share our interesting knowledge and stories on social media