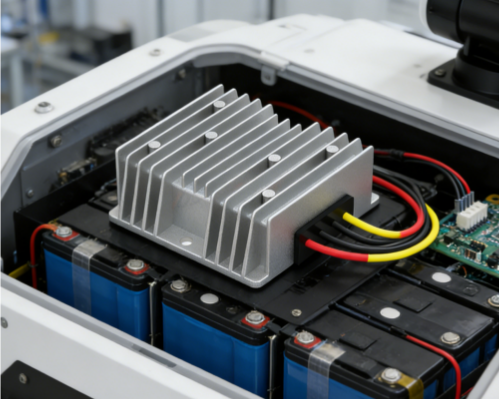

In contexts like industrial automation, communication base stations, and new energy devices, DC-DC converters act as the core components for power conversion, with their efficiency exerting a direct impact on equipment energy consumption, heat dissipation burden, and operational reliability. Particularly in industrial-grade applications, significant reductions in long-term operation and maintenance costs and extensions of equipment battery lifespan can be achieved with every 1% improvement in efficiency. The core of boosting efficiency lies in rational topology selection and high-precision component matching. This article will break down the practical paths for optimizing DC-DC converter efficiency from these two key dimensions.

Topology is the foundation determining the efficiency of DC-DC converters. Different topologies have distinct working principles and loss characteristics, making them suitable for various scenarios. Choosing the right topology lays a solid foundation for efficiency optimization. Among non-isolated topologies, Buck and Boost converters are widely used in low-to-medium power scenarios due to their simple structure and low loss. Buck converters are suitable for step-down requirements, with their efficiency bottleneck mainly in the on-resistance loss of switching transistors. By optimizing duty cycle control, efficiency can be increased to over 95% when the voltage difference between input and output is small. Boost converters are used for step-up scenarios, requiring focus on solving the reverse recovery loss of freewheeling diodes, which can be effectively reduced by integrating synchronous rectification technology.

Isolated topologies such as flyback, forward, and push-pull are suitable for industrial scenarios requiring electrical isolation. Flyback topology features a compact structure and low cost, making it ideal for low-to-medium power isolation needs. However, switching transistors withstand high voltage, resulting in significant switching loss under high-frequency conditions. By adopting a clamping circuit to absorb voltage spikes, efficiency can be improved to over 90%. Forward topology offers low output ripple and strong load capacity, suitable for medium-to-high power scenarios. Optimizing the magnetic reset circuit design can reduce core loss and further enhance efficiency. Push-pull topology is applicable for high-power, high-input voltage scenarios, and rational matching of switching transistor conduction timing can reduce cross-conduction loss.

Once the topology is determined, component selection becomes critical for efficiency optimization. The performance of core components such as switching transistors, diodes, inductors, and capacitors directly determines loss levels. As one of the main sources of loss, switching transistors should prioritize devices with low on-resistance (Rdson) and fast switching speed. MOSFETs are suitable for low-to-medium power scenarios due to their high-frequency performance; when selecting, a balance must be struck between Rdson and gate charge—lower Rdson reduces conduction loss but increased gate charge may elevate switching loss. IGBTs are ideal for high-power scenarios, requiring attention to switching loss and saturation voltage drop, with appropriate drive circuits to optimize switching timing.

Diode selection should focus on reverse recovery loss and forward voltage drop. Synchronous Rectifier (SR) diodes can replace traditional Schottky diodes, eliminating reverse recovery loss through synchronous control strategies. Especially in low-voltage, high-current scenarios, efficiency can be improved by 3%-5%. Schottky diodes, with their low forward voltage drop and fast switching speed, are suitable for high-frequency, low-power scenarios, but attention must be paid to the impact of reverse leakage current on efficiency.

Inductor and capacitor selection must balance loss and stability. Copper loss and core loss are the main loss points of inductors; enameled wire inductors with low Direct Current Resistance (DCR) should be selected, and core materials should prioritize ferrite or alloy materials with low high-frequency loss. Meanwhile, inductor value should be rationally designed to avoid magnetic saturation under high-frequency conditions. Capacitors should be selected based on operating frequency; for high-frequency scenarios, ceramic capacitors or polymer capacitors with low Equivalent Series Resistance (ESR) are preferred to reduce charge-discharge loss, while ensuring sufficient voltage margin to prevent capacitor heating and aging from affecting efficiency.

In addition, the matching between topology and components cannot be ignored. For example, LLC resonant topology requires precise matching of resonant inductor and capacitor parameters to ensure stable resonant frequency; synchronous rectification technology needs compatible drive chips to achieve precise synchronization with switching transistor timing, otherwise additional loss may occur. Simultaneously, integrating auxiliary measures such as PCB Layout optimization and heat dissipation design can further tap into efficiency potential.

In summary, enhancing the efficiency of DC-DC converters is no single-dimensional optimization, but a synergistic integration of topology selection and component configuration. In practical applications, based on scenario requirements—including power rating, input/output voltage range, isolation demands, and operating frequency—should the appropriate topology be selected, followed by targeted selection of core components and optimization of control strategies as well as auxiliary designs to maximize efficiency. For industrial-grade and communication-grade scenarios with stringent reliability requirements, a balance between stability and cost must also be struck in efficiency optimization to attain optimal overall performance.

We at IDEALPLUSING not only provide products, but also strive to provide customers with suitable power supply solutions and quotations.

Our core competitiveness lies in carefully selecting a variety of power supply options to help customers evaluate and choose the most suitable power supply solution.

We can offer AC DC power supply, DC AC inverter, AC AC power source(single phase or 3 phases),AC DC Ground Power Unit...

Share our interesting knowledge and stories on social media