What is meltblown cloth? Cut open a used medical mask and you will find that the mask has three layers: (inner layer) moisture absorption layer, (middle layer) core filter layer, and (outer layer) water barrier layer. Because according to national production regulations, medical masks contain at least 3 layers of non-woven fabrics (N95-level masks have been optimized in structure: (middle layer) core filter layer has more layers and thicker thickness).

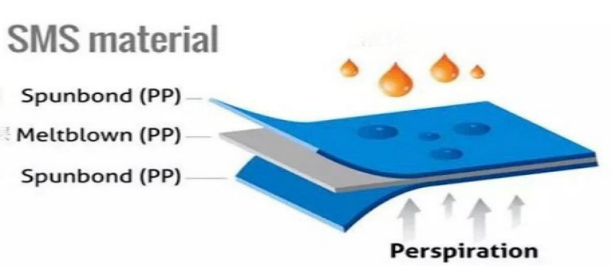

Structural diagram of SMS non-woven fabric

Meltblown cloth, commonly known as the "heart" of the mask, is the filter layer in the middle of the mask, which can filter bacteria and prevent the spread of germs. Meltblown cloth is a kind of polypropylene with a high melt index. It is a membrane formed by many crisscrossing fibers stacked in random directions. The fiber diameter ranges from 0.5 to 10 microns, and its fiber diameter is about one-thirtieth of a hair.

The special material for meltblown cloth is meltblown material-polypropylene with a high melt index. The higher the melt index of polypropylene, the finer the meltblown fibers, and the better the filterability of the meltblown cloth.

The melt index of ordinary polypropylene is about 30, while the melt index of polypropylene for meltblown non-woven fabrics is required to reach 1500-1800.

High-voltage power supply, also known as high-voltage generator, generally refers to a power supply with an output voltage of more than 5,000 volts. The output voltage of a general high-voltage power supply can reach tens of thousands of volts, or even hundreds of thousands of volts or higher.

The high-voltage power supply we usually refer to generally refers to a DC high-voltage power supply. There are two types of DC high-voltage power supplies: linear adjustment high-voltage power supplies and switching adjustment high-voltage power supplies.

There are two main directions for its technical development. One is to increase the power supply power, that is, high voltage and high current; the other is to reduce the power supply volume, that is, high voltage and small volume. Reducing the volume of the power supply is mainly to increase the switching frequency of the power supply. High-power power supplies are often larger in size, while small-volume power supplies are often smaller in current and lower in power.

In addition, high conversion efficiency, high load, high precision, and low ripple are also the research directions of high-voltage power supply designers.

For light For high-voltage power supplies for spectrum analysis (such as photomultiplier tube power supplies), low ripple is particularly important. This indicator will directly affect the accuracy of analysis and measurement. As for low ripple, the micro high-voltage power supplies produced by Dongwen High Voltage can control the ripple at 0.005%.

High-voltage power supplies have many uses. Dalian Jeman Technology Co., Ltd. is a professional high-voltage power supply manufacturer.

High-voltage power supplies have many uses. Dalian Jeman Technology Co., Ltd. is a professional high-voltage power supply manufacturer.

Its products mainly include X-ray machine high-voltage power supplies, laser high-voltage power supplies, spectrum analysis high-voltage power supplies, non-destructive testing high-voltage power supplies, semiconductor manufacturing equipment high-voltage power supplies, capillary electrophoresis high-voltage power supplies, non-destructive testing high-voltage power supplies, particle injection high-voltage power supplies in semiconductor technology, physical vapor deposition high-voltage power supplies (PVD), nano-lithography high-voltage power supplies, used for ion beam deposition, ion beam assisted deposition, electron beam evaporation, electron beam welding, ion source, DC magnetron reactive sputtering, glass/fabric coating, glow discharge, microwave processing high-voltage capacitor test, CRT display test, high-voltage cable fault test (PD testing), TWT testing, H-POT testing.

Particle accelerators, free electron lasers, neutron sources, cyclotron sources, capacitor inductor pulse generation networks, Marx high-voltage pulse generators, capacitor chargers.

Microwave heating, radio frequency amplification, nanotechnology applications, electrostatic technology applications, electrostatic spinning to prepare nanofibers, high-voltage power supplies for nuclear instruments, etc. High-voltage power supply products.

Application places

1. Colleges and universities, laboratories of scientific research institutes, electrical product testing and debugging.

2. High-voltage electrostatic spinning, high-voltage electrostatic dust removal, fume purification, electrostatic spraying, ozone generation equipment, electrostatic flocking, electrostatic spraying, etc.

3. Routine testing of electronic components.

4. Klystron, magnetron, electron gun test power supply, X-ray radio frequency test power supply.

5. High-voltage capacitor charging power supply.

6. Whole machine aging and all other occasions where high voltage output is required.

7. Electronic product testing, aging, gas discharge, gas dust removal, vacuum plating. Such as: plating power supply, sputtering coating power supply, etc.