An AC-DC converter is an electronic device that converts alternating current (AC) to direct current (DC). This conversion is critical for many electronic devices and systems, as they often require a DC power source to operate. So, do you know the factors that affect the operating temperature range of an ac to dc converter?

The operating temperature range of an ac and dc converter is related to several factors, including but not limited to:

Semiconductor materials

The semiconductor materials used in the converter, such as silicon, germanium, etc., have properties that change with temperature, affecting conversion efficiency and stability.

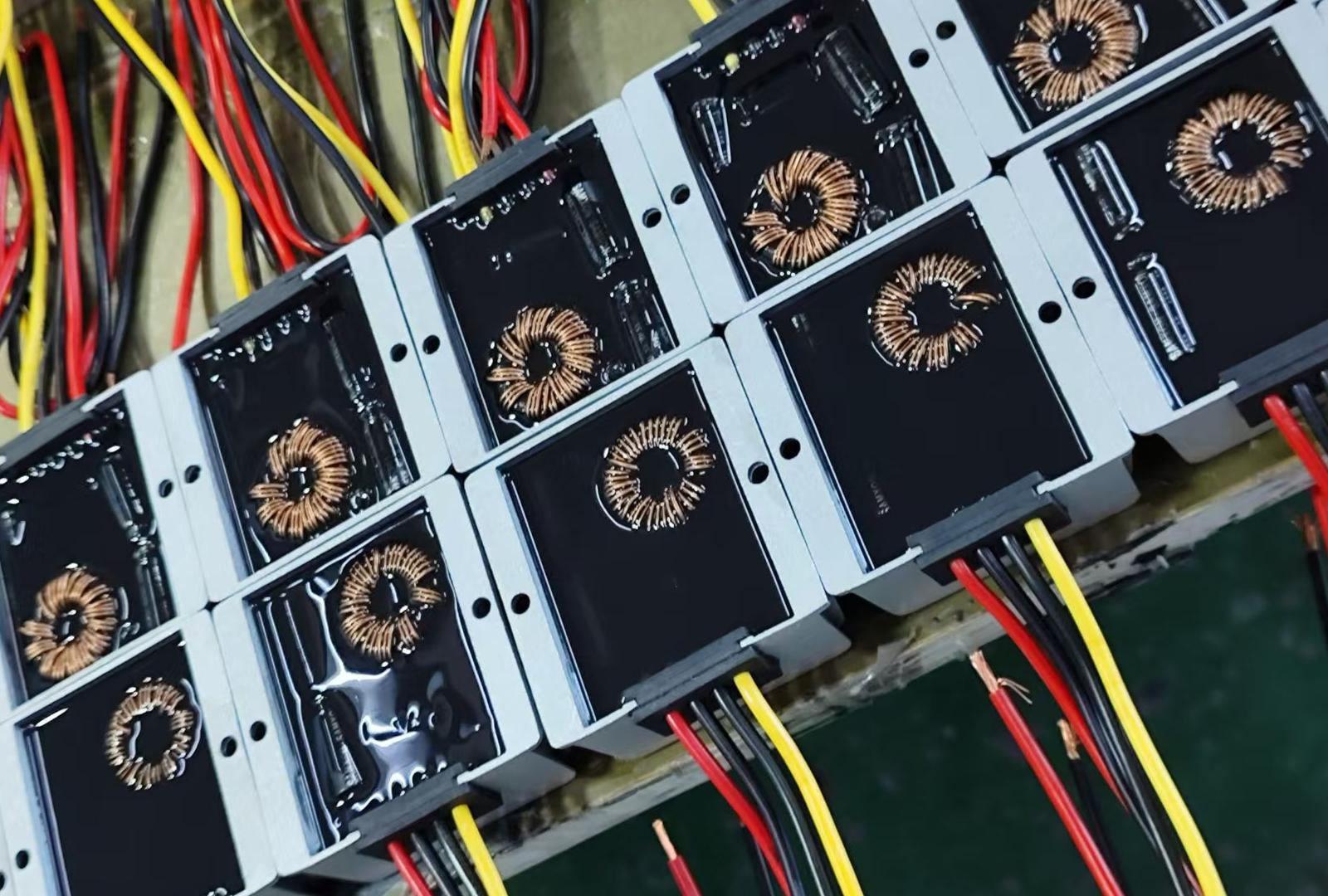

Capacitors and inductors

The temperature resistance and temperature coefficient of these components directly affect the operating temperature range of the converter. High temperatures may cause the dielectric material of the capacitor to age and reduce its life.

Heat sink design

Effective heat sink design is essential to maintain the converter within the appropriate operating temperature range. The material, shape, and size of the heat sink will affect the heat dissipation efficiency.

Environmental conditions

The ambient temperature, humidity, and dust in which the converter is located will affect its operating temperature range. High humidity and dust may reduce the efficiency of the heat sink and cause the temperature to rise.

Converter design

Includes circuit topology, control strategy, and protection mechanism. For example, soft switching technology can reduce switching losses and improve converter performance at high temperatures.

Input voltage range

The fluctuation of input voltage may affect the thermal design of the converter, and thermal stability at different input voltages needs to be considered.

Load conditions

The magnitude and variation of load current will affect the thermal loss of the converter, which in turn affects its operating temperature range.

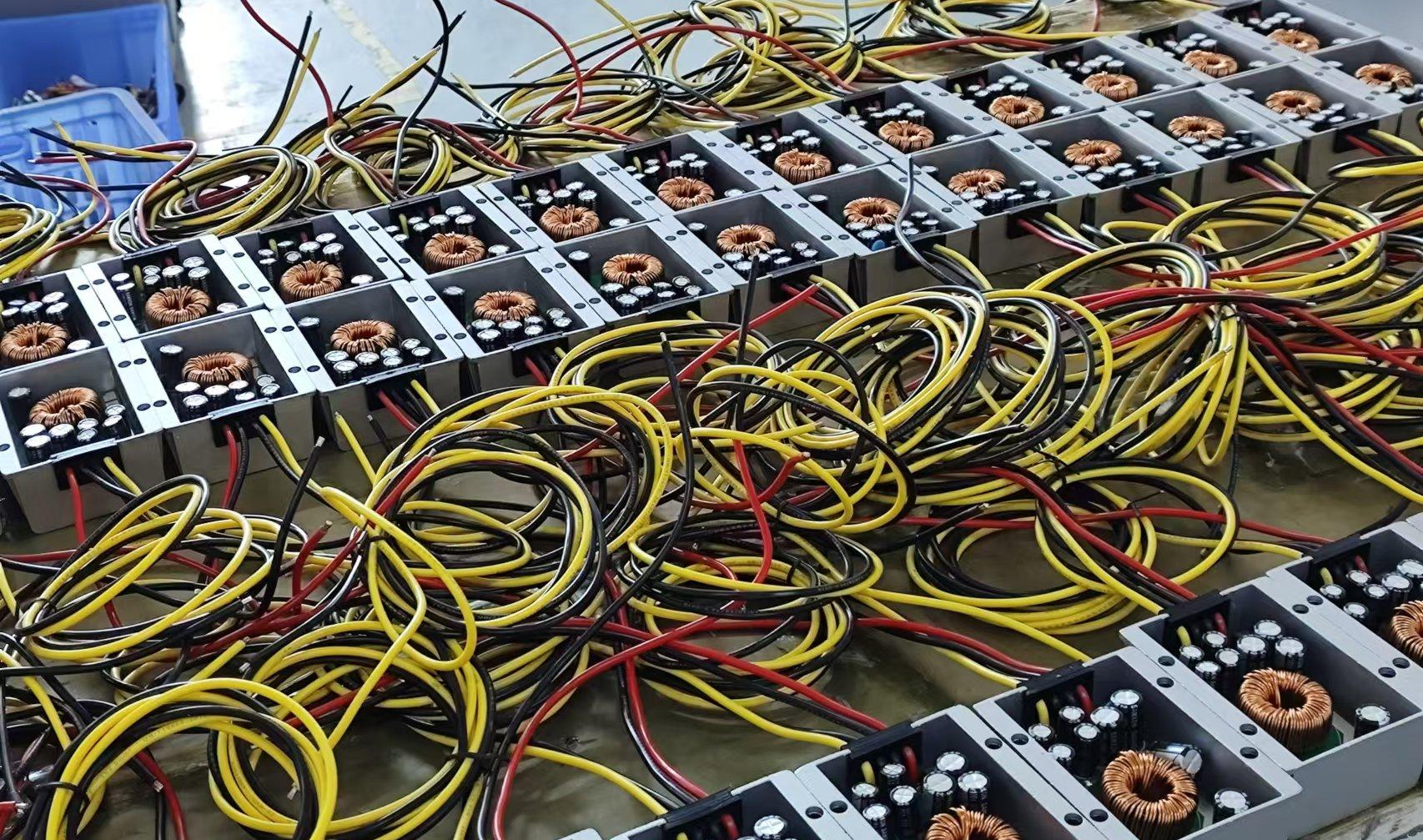

Manufacturing process

The soldering quality, component layout, and PCB design during the manufacturing process will affect the thermal performance and reliability of the converter.

Certification and standards

Different application areas may have different temperature requirements, such as industrial, automotive, or military, and these standards will impose specific requirements on the design and testing of the converter.

Long-term stability

The thermal stability of the converter in long-term operation is also an important consideration, and it is necessary to ensure that the converter can operate stably within the specified temperature range within the expected service life.

In summary, the operating temperature range of the AC DC converter is a complex issue that requires comprehensive consideration of multiple factors. Designers need to fully consider these factors during the design stage and ensure that the converter can operate reliably within the specified temperature range through appropriate testing and verification.