Ⅰ. Application of frequency converter in fan and water pump

The rated air volume and flow rate of commonly used fans and water pump equipment usually exceed the actual required air volume and flow rate, and the air volume and flow rate need to be changed during operation due to process requirements.

At present, the use of baffles or valves to adjust the air volume and flow rate is more common. Although the method is simple, it actually achieves the purpose of adjustment by artificially increasing resistance. This throttling adjustment method wastes a lot of electric energy. Recovering this part of the electric energy loss will have a great energy-saving effect.

When the air volume decreases and the fan speed decreases, the input power of its motor decreases rapidly. For example, when the air volume drops to 80% and the speed (n) also drops to 80%, its shaft power drops to 51% of the rated power; if the air volume drops to 50%, the shaft power will drop to 13% of the rated power, and its power saving potential is very large.

The above principle is also basically applicable to water pumps. Therefore, for fans and water pumps with a large air volume flow adjustment range, speed control is used instead of damper or valve adjustment, which is an effective way to achieve energy saving.

Most of the fans and water pumps are driven by AC asynchronous motors (most of the high-power ones are synchronous motors). The speed of the asynchronous motor or synchronous motor is proportional to the frequency f of the power supply. Changing the stator power supply frequency changes the speed of the motor. The variable frequency speed regulation device converts the 50Hz AC power of the power grid into AC power with adjustable frequency and voltage to drive the AC motor to achieve the speed regulator.

The characteristics of variable frequency speed regulation are high efficiency, no additional slip loss caused by speed regulation, large speed regulation range, high precision, and stepless speed regulation.

It is easy to realize municipality control and closed-loop control. Since the original squirrel cage motor can be used, it is particularly suitable for the technical transformation of old equipment. It not only maintains the advantages of the original motor's simple structure, reliability, durability, and convenient maintenance, but also achieves a significant effect of power saving. It is an ideal method for energy saving of fans and water pumps.

Ⅱ. Application of frequency converter in chemical industry

The frequency converter is applied to the transformation of automatic extraction of liquefied gas system equipment, which solves the big impact on the power grid and the cumbersome manual operation. The most important thing is energy saving and power saving as well as the realization of automatic extraction of liquefied gas system.

According to statistics, about 40% of electricity can be saved every month. According to this calculation, the cost can be recovered in half a year, and the effect is very significant.

Ⅲ. Application of frequency converter in plastic machinery

In the production process of plastic products, due to the characteristics of plastics, the specifications of products are various and the requirements of production processes are different, so many places need to adjust the speed of production machinery.

With the rapid development of power electronics technology, the technology of variable frequency speed regulation has matured, and variable frequency speed regulator has been widely used in various industries of the national economy. Its smooth stepless speed regulation, high reliability, high precision, and energy saving can improve the level of automation. To a certain extent, it has improved the automation level of plastic machinery and promoted the development of the plastic industry.

Ⅳ. Application of inverter in papermaking machinery

Papermaking enterprises are high-energy-consuming enterprises, consuming more than 500 degrees of electricity per ton of paper, and the energy consumption is very serious. From the perspective of equipment and type, more than 50% of the load is fans and pumps.

At present, these equipment basically use valves or baffles to adjust the air volume or liquid flow. A large amount of energy is consumed on the valves or baffles. The use of inverters for adjustment can greatly reduce losses, save electricity and have obvious economic benefits, which is worth promoting vigorously by enterprises.

Ⅴ. Application of inverter in energy saving of injection molding machines

Injection molding machines are equipment that heats, melts, stirs and pressurizes various plastics, injects plastic fluid into the mold control, and completes the one-time injection molding of workpieces.

Its process is basically the same, and can be roughly divided into 7 process processes: clamping, injection, pressure holding, melting, cooling, mold opening, ejector. Each process requires different pressure and flow, that is, the workpieces being processed do not all work under the maximum pressure or flow.

Its pressure and flow are regulated by pressure proportional valve and flow proportional valve, and the pressure and flow are controlled by adjusting the opening degree of pressure or flow proportional valve.

However, the input power of the oil pump motor does not change much in constant speed operation and each process. If the frequency converter is used to adjust the speed of the motor (oil pump) to achieve the regulation of pressure and flow, it is both economical and practical.

VI. Application of boiler variable frequency speed regulation technology

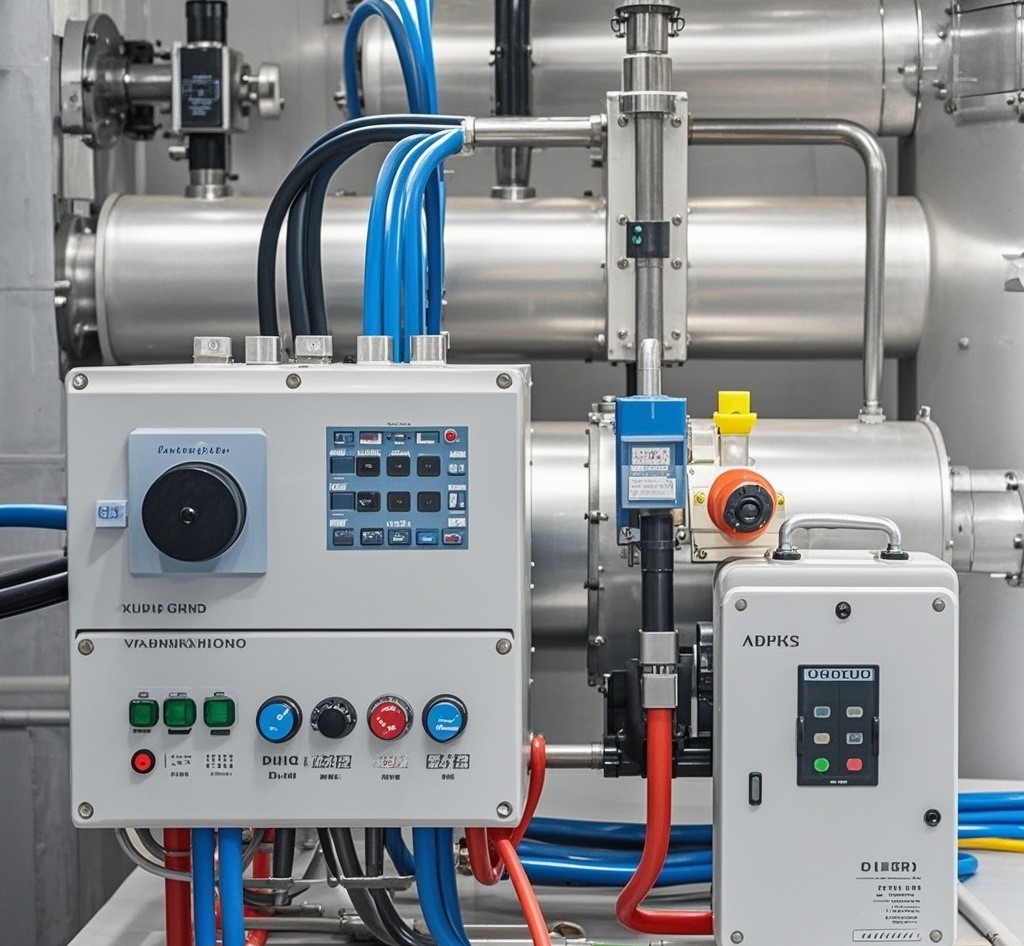

Boiler variable frequency speed regulation of blower (induced draft) control system

In order to improve the control level of boiler air volume and achieve energy saving effect, the use of variable frequency speed regulation to adjust the air volume is the preferred solution.

Because the application of variable frequency speed regulation technology can adjust the speed of the blower (induced draft) fan at any time according to the change of steam consumption, it reduces the noise pollution to the environment (the motor runs below the rated speed, and the wind noise decreases accordingly), which plays a certain role in improving the level of industrial hygiene.

Since the blower (induced draft) fan runs at a speed lower than the rated speed for a long time, the bearings of the motor and the fan are not easy to be damaged, which prolongs the service life, reduces the heat generation of the motor, reduces the maintenance volume, reduces the downtime, and saves a lot of maintenance costs.

VII. Application of variable frequency speed regulator in oil field walking beam pumping unit

First, the frequency converter has a soft start function, the current is small when starting, the impact on the power grid is small, and the energy consumption at start-up is greatly reduced.

Second, the introduction of frequency converter control can realize the automatic identification of the upper and lower strokes of the equipment, so as to control the motor operating frequency of the upper and lower strokes of the pumping unit, which can be adjusted respectively to change the operating speed of the upper and lower strokes of the pumping unit. The frequency converter energy consumption brake can also be accurately controlled to make the frequency converter more suitable for the operating conditions. In addition to the arbitrary adjustment of the pumping unit stroke, the pumping parameters of the pumping unit can be used to be more reasonable for different oil inputs. When adjusted appropriately, the pump filling coefficient can be increased, the pump leakage can be reduced, and the pump efficiency can be improved to achieve the purpose of increasing production.

Ⅷ. Application of frequency converter in central air conditioning cooling pump

The basic working principle of central air conditioning is to use compressor to force refrigeration cycle, transfer the heat in the building to the refrigerant through the refrigerant (usually water), and then transfer the heat to the atmosphere through the cooling tower. The energy consumed by the circulating water cooling pump and the freezing pump accounts for about 60% of the total energy consumption.

Air conditioning equipment is considered according to the maximum cooling capacity of the design working conditions, and most of the time it works under low load. Therefore, using frequency converter to drive will save a lot of energy.