Dielectric barrier discharge (DBD) is a non-equilibrium gas discharge with an insulating medium inserted into the discharge space, also known as dielectric barrier corona discharge or silent discharge. Dielectric barrier discharge can work at high pressure and a wide frequency range.

Dielectric barrier discharge (DBD) is a non-equilibrium gas discharge with an insulating medium inserted into the discharge space, also known as dielectric barrier corona discharge or silent discharge.

Dielectric barrier discharge can work at high pressure and a wide frequency range, and the usual working pressure is 10~10000. The power supply frequency can be from 50Hz to 1MHz. The design of the electrode structure is varied. A certain working gas is filled between the two discharge electrodes, and one or both electrodes are covered with an insulating medium. The medium can also be directly suspended in the discharge space or filled with a granular medium. When a sufficiently high AC voltage is applied between the two electrodes, the gas between the electrodes will be broken down and discharge will occur, that is, a dielectric barrier discharge will occur.

In practical applications, pipeline electrode structures are widely used in various chemical reactors, while flat electrode structures are widely used in the modification, grafting, surface tension enhancement, cleaning and hydrophilic modification of polymer and metal films and plates in industry.

Dielectric barrier discharge is usually driven by a sinusoidal alternating current (AC) high voltage power supply. As the supply voltage increases, the state of the reaction gas in the system will undergo three stages of change, that is, it will gradually change from insulation to discharge (breakdown) and finally breakdown.

When the supply voltage is relatively low, although some gases will have some ionization and free diffusion, the current is too small because the content is too small to cause a plasma reaction in the gas in the reaction zone. At this time, the current is zero. As the supply voltage gradually increases, the number of electrons in the reaction area also increases. However, when the breakdown voltage (breakdown voltage; avalanche voltage) of the reaction gas is not reached, the electric field between the two electrodes is relatively low and cannot provide the electrons with enough energy to make the gas molecules collide inelastically. The lack of inelastic collisions results in the number of electrons not being able to increase significantly. Therefore, the reaction gas is still in an insulating state and cannot produce discharge.

At this time, the current increases slightly with the increase of the voltage applied by the electrodes, but is almost zero. If the supply voltage continues to increase, when the electric field between the two electrodes is large enough to make the gas molecules collide inelastically, the gas will increase significantly due to the inelastic collision of ionization. When the electron density in the space is higher than a critical value and the Paschen breakdown voltage, many microdischarge filaments (microdischarge) are generated and connected between the two electrodes. At the same time, the luminous phenomenon can be clearly observed in the system. At this time, the current will increase rapidly with the increase of the applied voltage.

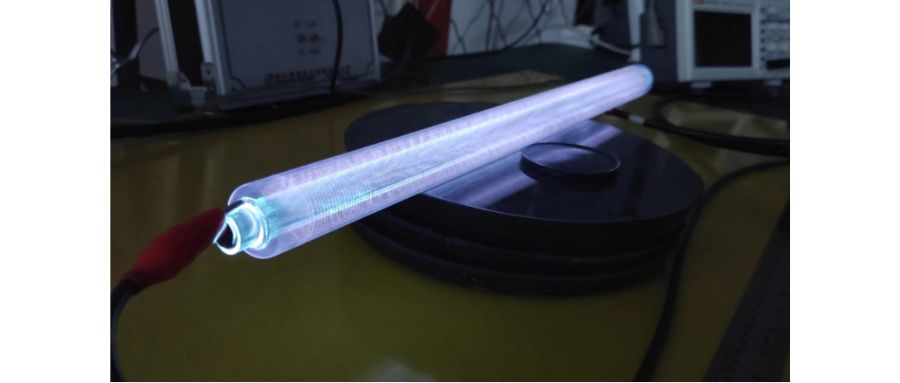

In dielectric barrier discharge, when the breakdown voltage exceeds the Paschen breakdown voltage, a large number of randomly distributed micro-discharges will appear in the gap. The appearance of this discharge looks like a glow discharge under low pressure from a distance, emitting a light close to blue. From a close look, it is composed of a large number of fine fast pulse discharges in the form of filaments. As long as the air gap between the electrodes is uniform, the discharge is uniform, diffuse and stable. These micro-discharges are composed of a large number of fast pulse current filaments, and each current filament is irregularly distributed in the discharge space and time. The discharge channel is basically cylindrical with a radius of about 0.1~0.3mm. The discharge duration is extremely short, about 10~100ns, but the current density can be as high as 0.1~1kA/cm2. Each current filament is a micro-discharge, which diffuses into surface discharge on the surface of the medium and appears as a bright spot.

These macroscopic characteristics will change with the power, frequency and medium applied between the electrodes. If a double dielectric is used and sufficient power is applied, the corona discharge will show a "filamentless" and uniform blue discharge, which looks like a glow discharge but is not a glow discharge. This macroscopic effect can be directly observed in the experiment through the transparent electrode or the air gap between the electrodes. Of course, the color of the discharge is different in different gas environments.

Although dielectric barrier discharge has been developed and widely used, its theoretical research has only been done in the past 20 years, and is limited to a relatively detailed discussion of microdischarge or a certain part of the entire discharge process. There is no theory that can be applied to DBD in various situations. The reason is that the working conditions of various DBDs are very different, and there are both physical and chemical processes in the discharge process, which affect each other. It is difficult to determine the specific process in the middle from the final result.

Because DBD will produce a large number of free radicals and excimers, such as OH, O, NO, etc., in the discharge process, their chemical properties are very active and they can easily react with other atoms, molecules or other free radicals to form stable atoms or molecules. Therefore, the characteristics of these free radicals can be used to treat VOCs, which is also very important in environmental protection.

In addition, DBD can be used to make excimer radiation light sources, which can emit narrowband radiation, and its wavelength covers infrared, ultraviolet and visible light spectrum, and does not produce radiation self-absorption. It is a high-efficiency, high-intensity monochromatic light source. In the DBD electrode structure, the pipeline electrode structure can also be used to make an ozone O3 generator. Now people have paid more and more attention to the research and application of DBD.

The material of the load medium dielectric barrier layer is generally glass or quartz glass. In special cases, ceramics, as well as thin enamel or polymer layers can also be used.

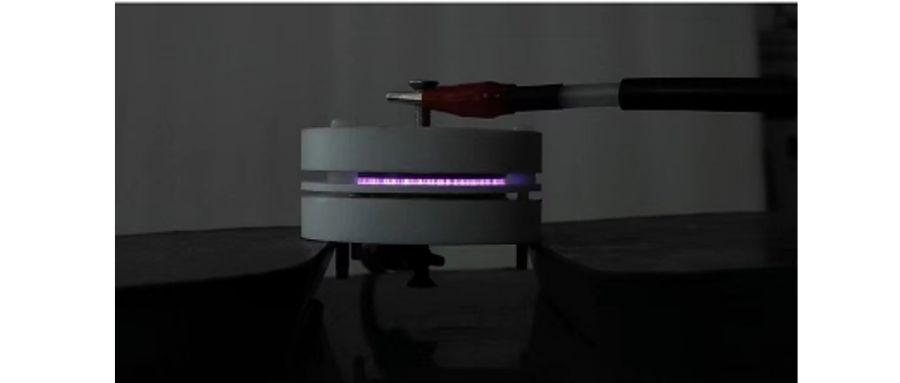

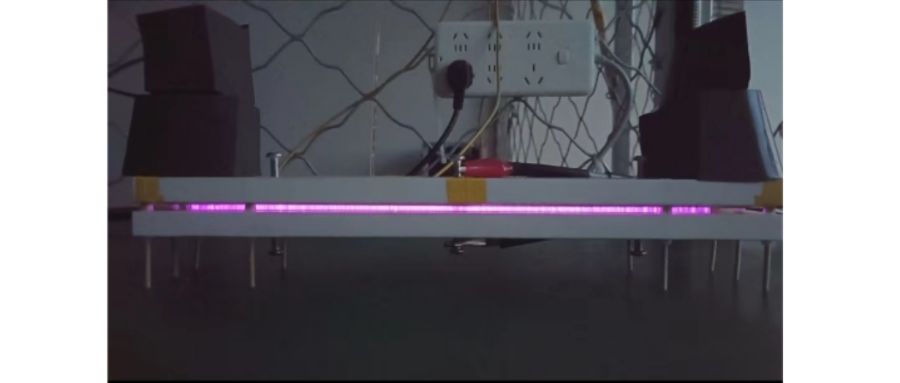

The following are pictures of the plasma effects produced by three different shapes of dielectric loads of IDEALPLUSING.

1. Plasma generated by using 99.99 rectangular pure copper as an electrode, 1mm thick ceramic sheet as a medium, and a high-voltage AC power supply with a model of IPS-ATAJ-10Kv-400mA-10-40kHz and an adjustable frequency of 10kHz-40kHz.

2. Using quartz glass tube as medium, using high voltage AC power supply model IPS-ATAJ-10Kv-400mA-20kHz fixed frequency 20kHz to generate plasma.

3. Using round stainless steel as electrode, using 2mm thick polytetrafluoroethylene as medium, using high voltage AC power supply model IPS-ATAJ-10Kv-400m-20kHz fixed frequency 20kHz to generate plasma.