With the rapid development of science and technology, complex modern circuits usually contain a large number of electronic components, such as microcontrollers, ICs, DSPs and FPGAs, each of which has specific supply voltage requirements. A distributed power system consisting of a shared "central" power supply and a large number of local converter modules has become the most energy-efficient solution to meet this requirement.

Modular DC-DC converters have long been recognized for their higher efficiency and reliability, but manufacturers have not used them in designs due to their relatively high cost, especially when large numbers of converters are needed. Although development costs are still increasing, the price of certified modules has dropped significantly compared to previous years. In addition, if other issues such as time to market are taken into account, modular converters are often a more cost-effective choice today.

DC-DC converters usually operate from low DC power supplies and are relatively simple components;

They form part of the printed circuit board, so are best mounted using a process along with other components.

At first glance, developing a converter seems to be a relatively simple task. But this is an illusion, because oftentimes, the details are the root of all problems with seemingly simple devices. When designing DC-DC converters, some characteristics of analog technology often cause difficult problems. For example, traces will generate capacitance or inductance that does not exist in the circuit diagram and is often impossible to predict. In addition, the performance of the transformer is not only affected by the ferrite material, but also depends on the range of the hysteresis loop in which the device operates. This can produce high levels of interference and may require secondary design iterations. The result is a delay in product launch, sometimes by several months. Manufacturers choose off-the-shelf power modules, which not only shortens development time but also minimizes commercial risks.

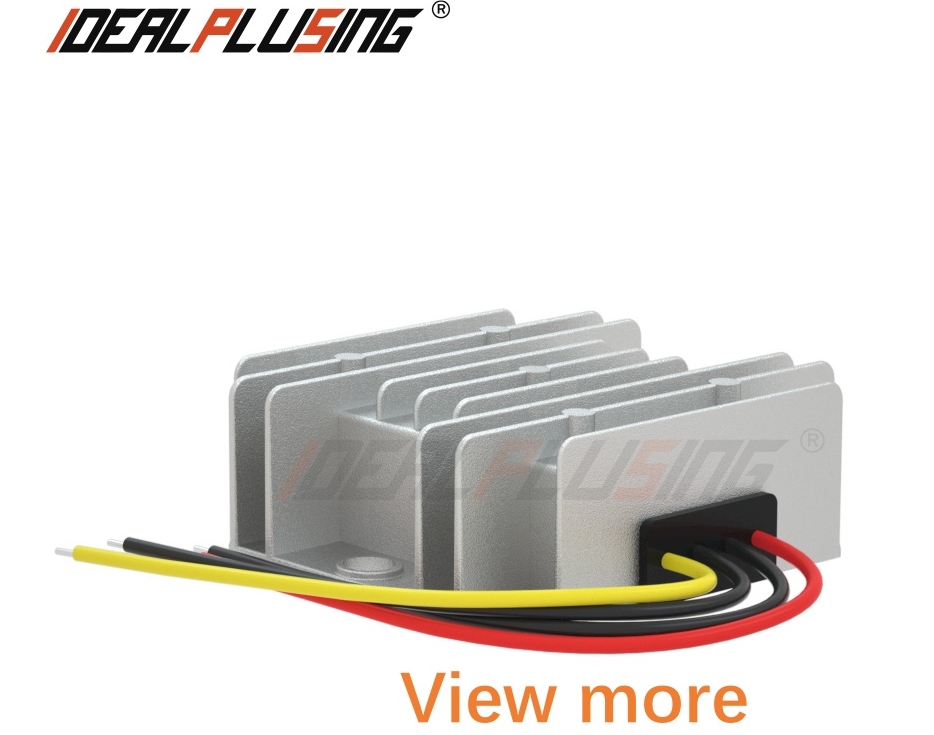

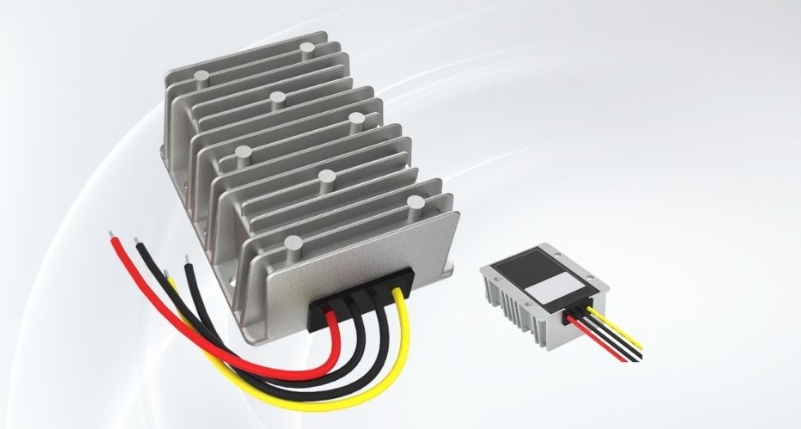

DC-DC converter modules are efficient and practical

The DC-DC converters of IDEALPLUSING, a Guangzhou-based company, are of high quality, high efficiency, outstanding reliability and cost-effectiveness. These DC/DC converters have been verified by thousands of applications and are widely used in many aspects. Modern designs usually require a large number of DC converters, so it is recommended that developers should pay close attention to the energy efficiency of each such component. Large converters usually operate at an energy efficiency rating of more than 90%, and it is difficult to achieve this rated energy efficiency using small DC-DC converters in the 1W-2W range, because each converter has a fixed static power consumption, and the small converter has a relatively higher ratio of such power consumption than the large converter.

If in this case, only focusing on the absolute rated energy efficiency at full load without considering the energy efficiency in the lower load range, there will be certain dangers. Generally speaking, all converters can achieve the highest energy efficiency when working close to the rated load. The lower the load, the lower the energy efficiency. But well-designed converters have stable high energy efficiency, especially in the important medium to low load range.