Power management is a challenging element in many areas of electronic design, not just in the industrial sector. By managing efficiency and thermal management issues in the best possible way, devices with very low energy consumption can be obtained. To obtain efficient DC-DC conversion, several characteristics need to be considered. Each of these approaches has its specific advantages and disadvantages depending on a range of operating conditions.

The design of DC-DC converters follows some specifications that must be approved depending on the application area. Examples of such specifications include input voltage range, output voltage value, output power, efficiency, electrical isolation between input and output, industrial standards. In the design of a DC-DC converter, many factors help determine the correct values for the relevant components. In addition, the selection of the best switching technology that is the basis for the operation of the DC-DC converter must be considered to further optimize the efficiency of the converter. The technology used (IC), materials, size and compliance with regulations are a major part of the final cost. The design of the power stage requires the identification of some characteristics such as transient tolerance and load characteristics (impedance range). Transient response is a good indicator of the performance level of the power supply. It is a measure of the ability of the DC current to withstand changes in load impedance.

Evaluation of DC-DC Converter Efficiency

System losses play an important role in evaluating the efficiency of DC-DC converters. Their analysis involves two types: the peak current in the inductor and the so-called switching losses caused by the charging and discharging phases of the converter circuit. Regarding the losses caused by the peak current in the inductor, two factors can be determined, one related to the drain-source resistance of the ON-OFF switching FET during conduction and the other to the DC resistance of the inductor. The switching losses or dynamic characteristics are mainly caused by the capacitive effects of the circuit. In particular, the drain-source parasitic switching capacitance of the FET and the diode must be considered. The energy losses in the inductor core are proportional to the switching frequency; in fact, as the inductor core losses increase, the frequency also increases. This type of leakage is due to the material and size of the core. The optimal choice of the inductor is mainly based on three considerations: the saturation current must be sufficiently higher than the maximum current flowing in the inductor; the continuous resistance of the inductor; and the physical size of the inductor. The FET must be able to withstand the drain-source voltage during the discharge of the inductor. In addition, the maximum leakage current must be higher than the peak current through the inductor. To minimize switching losses, FETs must have low gate-source and drain-source capacitance values.

The best choice of inductor is based on three main considerations: the saturation current must be high enough to be higher than the maximum current flowing in the inductor; the continuous resistance of the inductor; and the physical size of the inductor. The FET must be able to withstand the drain-source voltage during the inductor discharge. In addition, the maximum drain current must be higher than the peak current through the inductor. To minimize switching losses, FETs must have low gate-source and drain-source capacitance values. The best choice of inductor is based on three main considerations: the saturation current must be high enough to be higher than the maximum current flowing in the inductor; the continuous resistance of the inductor; and the physical size of the inductor. The FET must be able to withstand the drain-source voltage during the inductor discharge. In addition, the maximum drain current must be higher than the peak current through the inductor. To minimize switching losses, FETs must have low gate-source and drain-source capacitance values. The FET must be able to withstand the drain-source voltage during the inductor discharge. In addition, the maximum drain current must be higher than the peak current through the inductor. To minimize switching losses, FETs must have low gate-source and drain-source capacitance values. The FET must be able to withstand the drain-source voltage during the inductor discharge. In addition, the maximum drain current must be higher than the peak current through the inductor. To minimize switching losses, the FET must have low gate-source and drain-source capacitance values.

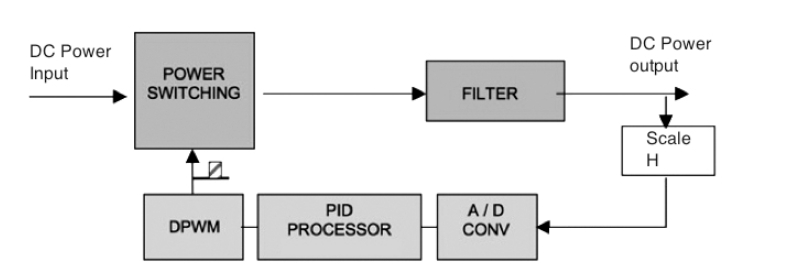

Digital Control

Digital control has proven to be the most reliable method of voltage regulation. Digital ICs allow fine-tuning of energy until dissipation is controlled during each operating cycle of the switching power supply. In a digital controller, an analog-to-digital converter (ADC) converts the difference between the measured value of the output voltage (scale) and the reference voltage (error voltage) into a digital value. The PID processor of the digital controller replaces the compensation network of the analog device. IDEALPLUSING's converter products also have the special advantage that they can be adjusted to different voltages by customers, and they are designed as a flexible DC element.

Medical

Medical grade DC/DC converters are often used to describe an increasingly popular class of converters. The main requirement is to find safe galvanic isolation between the input and output, usually expressed as isolation voltage. The ability of an isolated converter to withstand high voltages through its isolation barrier depends on the materials used to build the converter, the physical separation between the input and output traces on the internal PCB, and the ability of the transformer to withstand the stress between the input and output windings. The simplest solution for transformer construction is to use windings with a coating thickness or multiple layers of coating to ensure adequate insulation. However, with the trend towards miniaturization, this solution has reached its limits.

Apart from insulation resistance, the other most critical specification for DC/DC converters is the operating temperature range. Efficient converters with low internal power dissipation can operate at high temperatures without overheating.

In summary, the design of a power system involves a series of trade-offs between design factors, such as size, cost, and efficiency. Generally speaking, to design a power stage, some performance needs to be determined, such as transient tolerance, ripple voltage, and load characteristics. In order to achieve systems with longer operating time and smaller size, more and more system designers are focusing on improving power conversion efficiency with advanced circuit topologies by better managing battery characteristics.