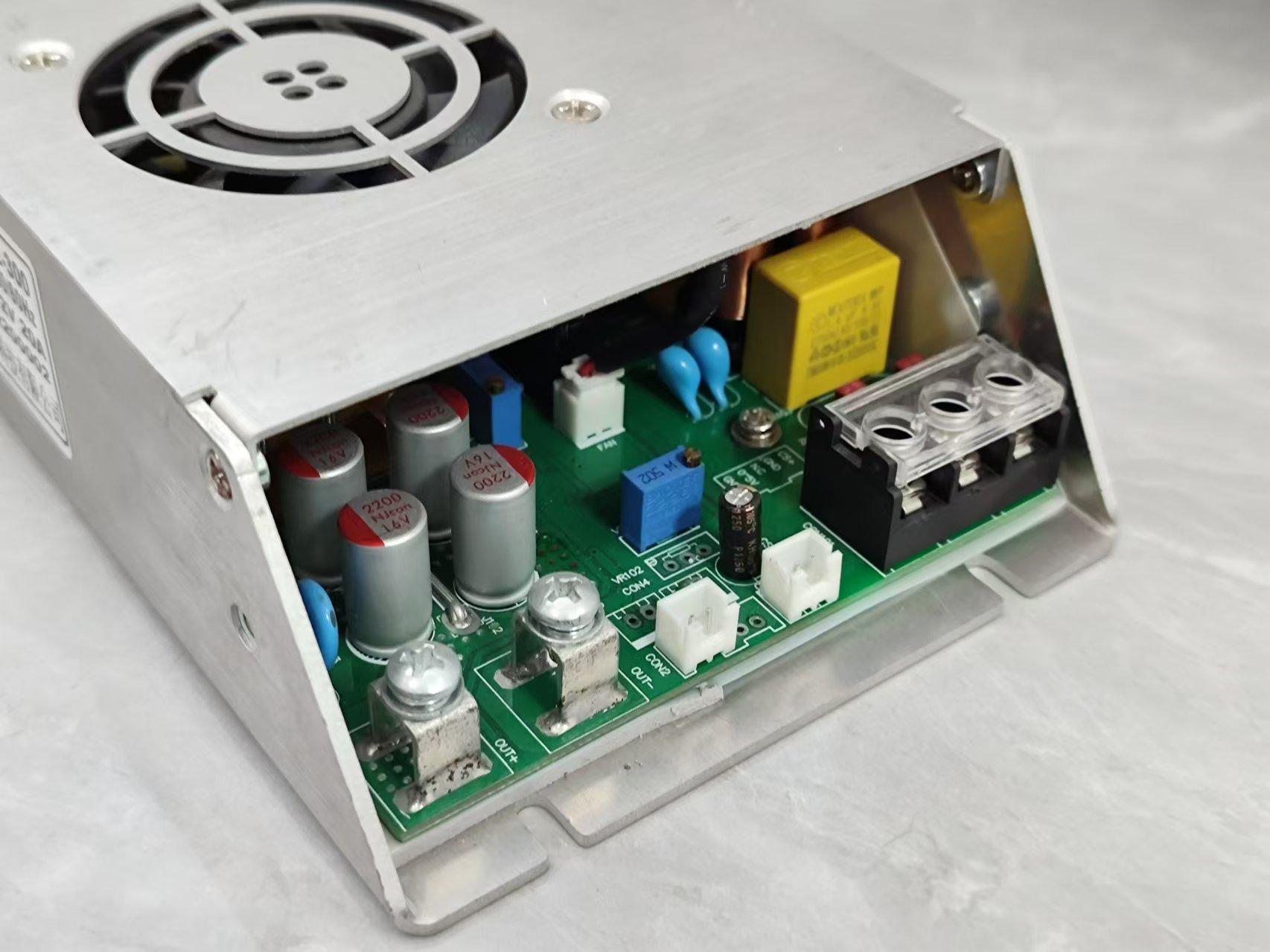

The main component of IDEALPLUSING communication switching power supply is a high-frequency switching rectifier, which has gradually matured with the development of power electronics theory and technology and power electronic devices. Rectifiers using soft switching technology have lower power consumption, lower temperature, and significantly reduced volume and weight, and the overall quality and reliability are constantly improving. However, every time the ambient temperature rises by 10°C, the life of the main power components is reduced by 50%. The reason for such a rapid decline in life is due to temperature changes. Fatigue failure caused by various microscopic and macroscopic mechanical stress concentrations, ferromagnetic materials and other components will develop various types of microscopic internal defects under the continuous action of alternating stress during operation. Therefore, ensuring effective heat dissipation of the equipment is a necessary condition to ensure the reliability and life of the equipment.

Ⅰ. The impact of cooling methods on the operating temperature of the power supply

The heat dissipation of the power supply generally adopts two methods: direct conduction and convection conduction. Direct heat conduction is the transfer of heat energy from the high temperature end to the low temperature end along the object, and its heat conduction capacity is stable. Convection conduction is the process in which liquid or gas makes the temperature tend to be uniform through rotation. Since convection conduction involves the power process, the cooling is relatively smooth.

Install the radiator on the metal radiator, and transfer energy by squeezing the hot surface to achieve high and low energy bodies. The energy that can be radiated by the large area of the heat sink is not much. This heat conduction method is called natural cooling, which has a long delay time for heat dissipation. Heat transfer Q = KA△t (K heat transfer coefficient, A heat transfer area, △t temperature difference). If the indoor ambient temperature is high, the absolute value of △t is small, and the heat dissipation performance of this heat transfer method will be greatly reduced.

Add a fan to the power supply to quickly discharge the heat accumulated in the energy conversion out of the power supply. The continuous air supply of the fan to the heat sink can be regarded as convective energy transfer. It is called fan cooling, and the delay time of this heat dissipation method is short and long. Heat dissipation Q = Km△t (K heat transfer coefficient, m heat transfer air mass, △t temperature difference). Once the fan speed decreases or stops, the m value will decrease rapidly, and the heat accumulated in the power supply will be difficult to dissipate, which will greatly increase the aging speed of electronic components such as capacitors and transformers in the power supply and affect the stability of its output quality, eventually leading to component burnout and equipment failure.

Ⅱ. Main methods and advantages and disadvantages of communication power supply heat dissipation

The design of communication switching power supply cooling technology must first meet the various technical performance requirements of the industry. In order to better adapt to the special environment of the communication room, its cooling method is required to be highly adaptable to changes in ambient temperature. At present, the commonly used cooling methods for rectifiers are natural cooling, pure fan cooling, and a combination of natural cooling and fan cooling. Natural cooling has the characteristics of no mechanical failure and high reliability; no air flow, less dust, which is conducive to heat dissipation; no noise. Pure fan cooling has the characteristics of light equipment weight and low cost. The technology combining fans and natural cooling has the characteristics of effectively reducing the size and weight of equipment, long fan service life, and strong fan fault adaptive ability.

Natural cooling

Natural cooling is the traditional cooling method of the early switching power supply. This method mainly relies on a large metal heat sink for direct heat conduction heat dissipation. Heat exchange Q = KA△t (K heat exchange coefficient, A heat exchange area, △t temperature difference). When the output power of the rectifier increases, the temperature of its power components will rise, and the △t temperature difference will also increase. Therefore, when the heat exchange area of the rectifier A is sufficient, its heat dissipation has no time lag, the temperature difference of the power components is small, and its thermal stress and thermal shock are small. However, the main disadvantage of this method is that the heat sink is large in size and weight. The winding of the transformer is to reduce the temperature rise as much as possible to prevent the temperature rise from affecting its working performance, so the margin of its material selection is large, and the transformer is also large in size and weight. The material cost of the rectifier is high, and maintenance and replacement are inconvenient. Because it does not require high environmental cleanliness, it is currently used in some small professional communication networks for small-capacity communication power supplies, such as electricity, petroleum, radio and television, water conservancy, national security, public security, etc.

Fan cooling

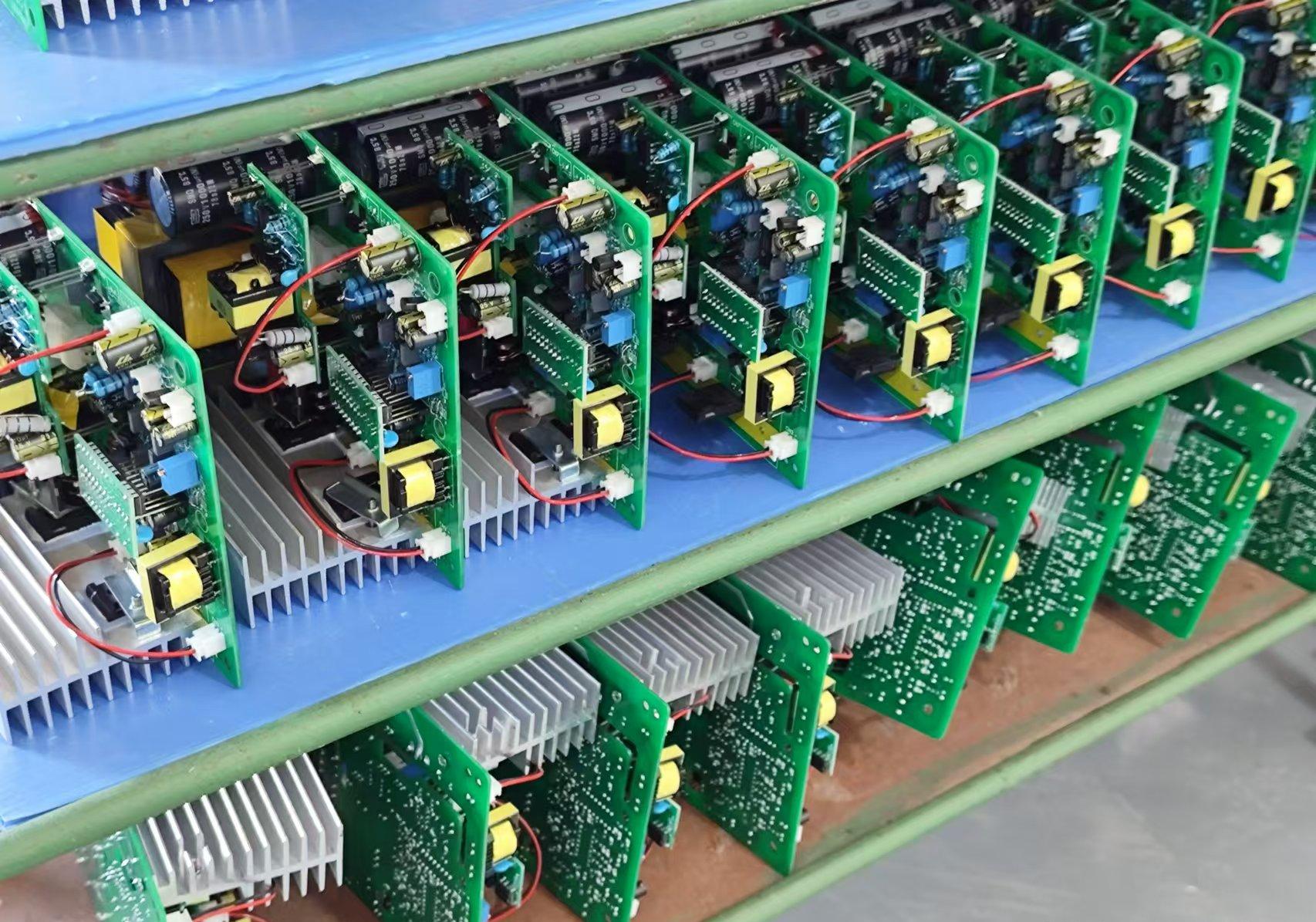

With the development of fan manufacturing technology, the working stability and service life of the fan have made great progress, and its average trouble-free time is 50,000 hours. After using fan heat dissipation, the bulky radiator can be removed, which greatly improves the volume and weight of the rectifier and greatly reduces the cost of raw materials. With the intensification of market competition and the decline in market prices, this technology has become the current main trend.

The main disadvantage of this method is that the average trouble-free time of the fan is shorter than the 100,000 hours of the rectifier. If the fan fails, the failure rate of the power supply will be greatly affected. Therefore, in order to ensure the service life of the fan, the speed of the fan changes with the temperature in the equipment. Its heat dissipation Q = Km△t (K heat transfer coefficient, m heat exchange air quality, △t temperature difference). m heat exchange air quality is related to the speed of the fan. When the output power of the rectifier increases, the temperature of its power element will rise. There is a large time lag from the change in the temperature of the power element to the rectifier being able to detect this change, and then to increasing the speed of the fan to enhance heat dissipation. If the load changes frequently or the mains input fluctuates greatly, the power components will experience rapid changes in temperature. The thermal stress and thermal shock generated by this sudden semiconductor temperature difference will cause stress cracks in different material parts of the components, causing them to fail prematurely.

Combination of fan and natural cooling

Due to changes in ambient temperature and load, the power supply consumes heat energy when working. The combination of fan and natural cooling can dissipate the heat energy faster. This method can reduce the radiator area while increasing the fan heat dissipation, so that the power components work under relatively stable temperature field conditions, and the service life will not be affected by changes in external conditions. This not only overcomes the shortcomings of the lagging heat dissipation regulation of power components in pure fan cooling, but also avoids the impact of the low service life of the fan on the overall reliability of the rectifier. Especially when the ambient temperature of the computer room is very unstable, the cooling technology combining air cooling and self cooling has better cooling performance. The material cost of the rectifier in this way is between pure fan cooling and natural cooling, with low weight and easy maintenance.

Especially when using intelligent air cooling and self-cooling technology, the rectifier can keep the module temperature rise small under low load working conditions, and the module fan is in a low-speed operation state. Under high load working conditions, the module heats up. The module temperature rises by more than 55°C. The fan speed increases linearly with temperature changes. Fan fault detection in place, after the fan fails, the fan fault current limiting output, and the fault alarm. Since the number of fan operation is related to the load size, the service life of the fan is longer than that of pure air cooling, and its reliability is greatly improved.

Ⅲ. The influence of temperature on the performance and life of communication switching power supply

The relationship between operating temperature and the reliability and life of power electronic components

The power supply is an electric energy conversion device. During the conversion process, it needs to consume some electric energy, and this electric energy is converted into heat and released. The working stability and aging speed of electronic components are closely related to the ambient temperature. Power electronic components are composed of a variety of semiconductor materials. Since the loss of power components during operation is dissipated by their own heat, the thermal cycle of multiple materials with different expansion coefficients will cause very significant stress, and may even cause instantaneous fracture and component failure. If the power components work under abnormal temperature conditions for a long time, fatigue will be caused, which will lead to fracture. Since semiconductors have a thermal fatigue life, they should work in a relatively stable and low temperature range.

At the same time, rapid changes in temperature will temporarily produce semiconductor temperature differences, which will produce thermal stress and thermal shock. The components are subjected to thermal-mechanical stress. When the temperature difference is too large, stress cracks will be generated in different material parts of the components. The components will fail prematurely. This also requires that the power components should work in a relatively stable operating temperature range, reduce the rapid temperature changes, eliminate the impact of thermal stress shock, and ensure the long-term and reliable operation of the components.

The influence of operating temperature on the insulation capacity of the transformer

After the primary winding of the transformer is energized, the magnetic flux generated by the coil flows in the iron core. Since the iron core itself is a conductor, an induced potential will be generated on the plane perpendicular to the magnetic field lines, forming a closed loop on the cross section of the iron core and generating current, which is called "eddy current". This "eddy current" increases the loss of the transformer, and causes the iron core of the transformer to heat up and the temperature rise of the transformer to increase. The loss generated by the "eddy current" is called "iron loss". In addition, the copper wire used in winding the transformer has resistance. When current flows through, this resistance will consume a certain amount of power. This part of the loss is converted into heat and consumed, which is called "copper loss". Therefore, iron loss and copper loss are the main reasons for the temperature rise of the transformer.

As the operating temperature of the transformer rises, the coil will inevitably age. When its insulation performance decreases, the ability to resist the impact of the main power will be weakened. At this time, if there is a lightning strike or a main power surge, the high reverse voltage appearing in the primary of the transformer will break down the transformer, causing the power supply to fail. At the same time, there is also a risk of high voltage being connected to the main communication equipment, causing damage to the main equipment.

In order to ensure the reliable and stable operation of the rectifier of the communication switching power supply, reducing its operating temperature rise is a key technology. It adopts a combination of intelligent air cooling and self-cooling technology. It has technical advantages such as stronger environmental adaptability, long service life, reliability and stability.

The communication switching power supply adopts a cooling method that combines fans and natural cooling. It can effectively reduce the internal working temperature of the rectifier and extend the service life of the device when the ambient temperature is high. It can also reduce the speed of the rectifier fan when the ambient temperature is low and the load is low, thereby extending the service life of the fan. The heat sink is used for heat dissipation, and the device spacing and creepage distance can be relatively far. In the case of high humidity, the safety performance is high. The rectifier is small in size and light in weight, making maintenance work easy.