Electric vehicles are equipped with large, high-voltage lithium-ion batteries and low-voltage lead-acid batteries, which are also used in engine vehicles. Both batteries need to be charged, lithium-ion batteries need to be charged at charging stations, and lead-acid batteries need to be charged from lithium-ion batteries. At this time, the device that converts a certain dc power into a different dc power is a dc dc converter. We will explain the functions and system configuration of dc/dc converters.

Overview of DC/DC Converters

All devices in electric vehicles rely on electricity. The driving motor and other devices rely on the power of large/high-voltage lithium-ion batteries, and many other on-board devices (ECU, cameras, lights, etc.) rely on the power of low-voltage lead-acid batteries. If the lead-acid battery is not charged, it will run out of power, so it needs to be charged from the lithium-ion battery. Among them, the device that converts high-voltage dc power into low-voltage dc power is a dc dc converter. By converting to low voltage, various on-board devices in electric vehicles can operate at an appropriate voltage.

The difference between high voltage and low voltage use

The use of high voltage

In order to operate the driving motor, high voltage is required. Since the motor requires high power, if you try to make it work at a low voltage, a large current will be generated, which will increase the loss in the circuit and reduce the conversion efficiency. In order to improve efficiency, a high voltage (400V or more) is needed to suppress the current.

Uses of low voltage

Low voltage is used for devices other than those related to the driving motor (various devices in the car and headlights, etc.). In addition, even for high-voltage devices, the internal control circuit operates at a low voltage. Therefore, a dc-dc converter that converts from high voltage to low voltage is indispensable.

Why is the low voltage 12V

Early cars started the engine manually, and later a mechanism that used a starter motor to start was developed. In order to drive the starter motor, a lead-acid battery was installed. At present, a 12V battery pack composed of 6 lead-acid battery cells is used in cars (each battery cell is about 2.1V). However, the starter motor of the engine on the truck uses a large motor, so a 24V battery pack (12V battery × 2) is usually used.

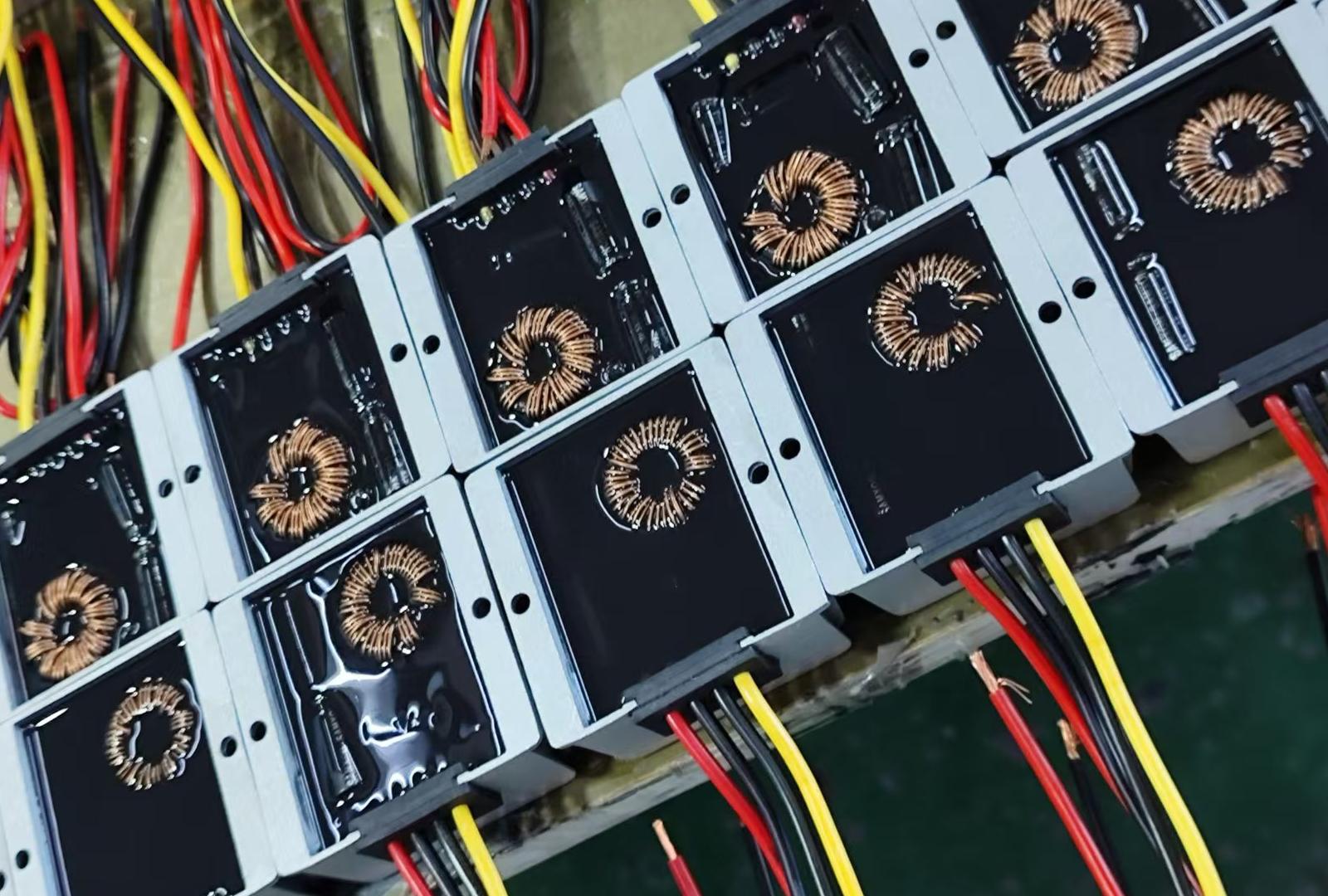

About the circuit structure of DC/DC converter

Voltage detection (input side): Measure the input voltage from the lithium-ion battery

Noise filter (input side): Use capacitors and coils to remove noise

Voltage conversion circuit: Convert voltage by switching through insulation transformers and FETs

Noise filter (output side): Use capacitors and coils to remove noise

Voltage detection (output side): Measure output voltage

Control circuit: Control conversion circuit, etc.

DC/DC converter: Supply power to the control circuit

Communication circuit: Communication circuit with the outside

In electric vehicles, most of the on-board devices other than the motor operate at a voltage much lower than the vehicle's main power supply voltage. Among them, the device that converts the high-voltage dc output of the lithium-ion battery into low-voltage dc is the dc dc converter. In the future, as the number of electric vehicles increases, the number of dc/dc converters installed will also increase.