With the rapid development of power electronics technology, AC/DC converters, as key devices for converting AC power to DC power, are widely used in numerous fields, including industrial automation, new energy, and consumer electronics. Their performance directly impacts the stability, safety, and energy efficiency of the entire electronic system. AC/DC converters can be categorized into two types: isolated and non-isolated, depending on whether they provide electrical isolation. These two types differ significantly in structure, performance, and application scenarios, making understanding these differences crucial for selecting the right converter.

The core feature of an isolated AC/DC converter is the electrical isolation barrier between the input and output, typically achieved through a transformer. The transformer not only converts voltage but, more importantly, completely isolates the AC input from the DC output, eliminating a direct current path between the two. This isolation design offers numerous important advantages. First, in terms of safety, isolated converters effectively prevent high voltage or fault currents on the input side from being transmitted to the output, thereby protecting connected equipment and operators. In medical equipment, patients come into direct contact with electronic devices. If a device malfunctions, such as leakage, an isolated converter can prevent dangerous current from flowing through the body, significantly reducing the risk of medical accidents. Furthermore, isolation helps suppress electromagnetic interference (EMI) and radio frequency interference (RFI). Since there's no direct electrical connection between the input and output, interference signals from the input side are unlikely to be transmitted to the output side. Simultaneously, interference generated on the output side is prevented from being fed back to the input side. This is crucial for electronic systems requiring high precision and low noise, such as communications equipment and measuring instruments. Furthermore, isolated converters can facilitate energy transfer between systems with different potentials, facilitating system grounding design and preventing the impact of common-mode interference on system performance.

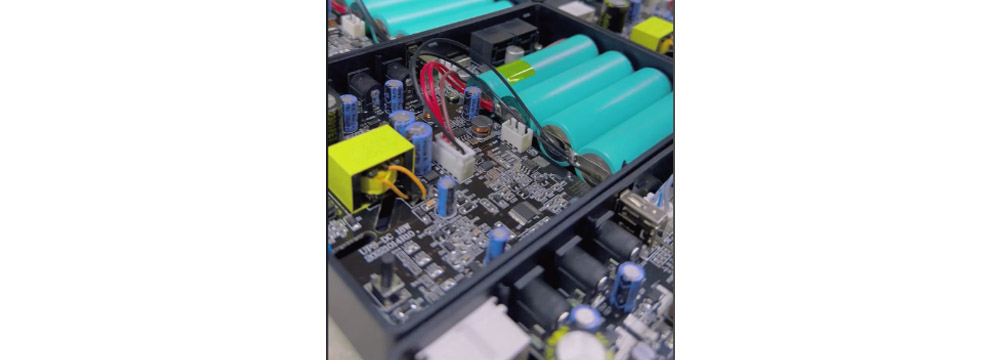

Isolated AC/DC converters can be categorized into various types based on their topology, including flyback, forward, push-pull, half-bridge, and full-bridge. The flyback converter boasts a relatively simple structure and low cost, making it suitable for low- and medium-power applications, such as mobile phone chargers and set-top box power supplies. Its operating principle is that when the switch is on, energy is stored in the transformer's primary winding. When the switch is off, this energy is transferred to the load through the secondary winding. Forward converters transfer energy directly to the load when the switch is on, resulting in high transformer utilization and suitable for medium-power applications such as industrial control power supplies. Push-pull, half-bridge, and full-bridge converters are suitable for high-power applications such as server power supplies and new energy inverters. By alternating multiple switches, they improve power conversion efficiency and reliability. Unlike isolated AC/DC converters, non-isolated AC/DC converters lack an electrical isolation barrier between the input and output. Instead, they share a common ground terminal, allowing current to flow directly between the input and output. This structure offers advantages such as small size, light weight, low cost, and high efficiency. By eliminating isolation components such as transformers, the circuit structure is simpler, making it suitable for integration into small electronic devices. In LED driver power supplies, non-isolated converters can be tightly integrated within lighting fixtures, saving installation space. In portable electronic devices such as tablets and portable players, non-isolated converters can reduce weight and improve portability. Non-isolated AC/DC converter topologies include buck (step-down), boost (boost), and buck-boost (step-up/step-down). Buck converters are suitable for applications where the output voltage is lower than the input voltage, such as charging circuits for battery-powered devices. Boost converters are suitable for applications where the output voltage is higher than the input voltage, such as maximum power point tracking circuits in solar photovoltaic systems. Buck-boost converters can adjust the output voltage within a range above and below the input voltage, offering greater flexibility and suiting applications with wide voltage fluctuations.

When selecting an AC/DC converter, safety requirements should be a primary consideration. For applications with high safety requirements, such as medical equipment, high-voltage equipment in industrial control, or electronic devices that come into contact with human body, an isolated converter is the obvious choice. In these applications, a leakage current could cause serious injury or damage to personnel or equipment. The electrical isolation of an isolated converter effectively blocks the leakage current path, ensuring safety. However, for applications where safety requirements are less stringent and other internal safety measures are already in place, such as small household appliances and low-voltage, low-power electronic toys, non-isolated converters can be considered to reduce cost and size.

Secondly, electromagnetic compatibility (EMC) requirements are also a key consideration when selecting a converter. In environments sensitive to electromagnetic interference, such as communications rooms and medical equipment rooms, isolated converters, thanks to their isolation, effectively suppress interference transmission and are therefore more likely to meet EMC requirements. Non-isolated converters, however, due to the direct electrical connection between the input and output, can easily become a transmission path for interference, potentially disrupting surrounding equipment and being susceptible to external interference. Therefore, isolated converters are generally preferred in applications with strict EMC requirements. If a non-isolated converter is unavoidable, additional filtering, shielding, and other measures are required to improve electromagnetic compatibility, which can increase system complexity and cost.

Power rating is also a key factor in selecting an AC/DC converter. Generally speaking, isolated converters are more suitable for medium- to high-power applications. This is because high-power conversion generates large amounts of energy, and isolation design allows for better energy transfer and distribution, while also improving system safety and reliability. However, due to structural limitations, non-isolated converters can experience heat dissipation difficulties and reduced efficiency during high-power conversion, making them more suitable for lower-power applications. Of course, with technological advancements, the power levels of non-isolated converters are also increasing. However, overall, isolated converters still dominate the high-power market.

Furthermore, converter efficiency and reliability must be considered. At the same power level, non-isolated converters generally have slightly higher efficiency than isolated converters due to the lack of transformer energy losses. However, in high-power applications, isolated converters can achieve higher efficiency and reliability through appropriate topology and heat dissipation design. Furthermore, the isolation function of isolated converters can reduce fault propagation and improve overall system reliability. However, since the input and output of non-isolated converters are directly connected, a fault on the input side can easily affect devices on the output side.

In practical applications, there are also special circumstances that require comprehensive consideration. For example, in applications where safety requirements are combined with size and cost constraints, highly integrated isolated converter modules can be selected. These modules utilize optimized designs to minimize size and cost while maintaining isolation performance. For example, in systems requiring multiple outputs, isolated converters can achieve multiple isolated outputs through multiple secondary windings, preventing interference between outputs. However, the multiple outputs of non-isolated converters are susceptible to mutual interference, requiring complex voltage regulation and filtering circuits to ensure output quality.

In summary, isolated and non-isolated AC/DC converters each have their own characteristics and applicable scenarios. Isolated converters, with their advantages of high safety, strong anti-interference capabilities, and suitability for medium to high power, are widely used in key fields such as medical, industrial control, and communications. Non-isolated converters, with their small size, low cost, and high efficiency, play an important role in consumer electronics and small devices. When selecting a converter, comprehensive consideration should be given to factors such as safety requirements, EMC requirements, power level, cost budget, and size and weight constraints for the specific application scenario to select the most suitable AC/DC converter and ensure stable, safe, and efficient operation of the entire electronic system.

Share our interesting knowledge and stories on social media