There is always going to be some level of risk when it comes to electrical components, with the primary concerns being fire and shock. To prevent such incidents from occurring, this article conducts an in-depth discussion on power supply safety, including the power supply safety issues we may encounter, how to prevent power supply safety accidents, and an introduction to electrical safety certification.

The most common safety concerns when dealing with power supplies, Before unpacking the power supply safety standards it’s important that you’re aware of the various safety concerns dealing with power supplies.Here is a detailed introduction:

Electrical Shock is the most common and usually the most dangerous. High-voltage power supplies generate dangerous current levels that can cause serious injury or death. Direct contact with live terminals, faulty wiring, or inadequate insulation are major causes of electrical shock. Next is another very common problem: power supply overheating. Without adequate ventilation or cooling, PSU overheating is common and can lead to equipment failure or fire. This occurs when power supplies are installed in confined spaces without proper airflow or operate at a load beyond their rated capacity.

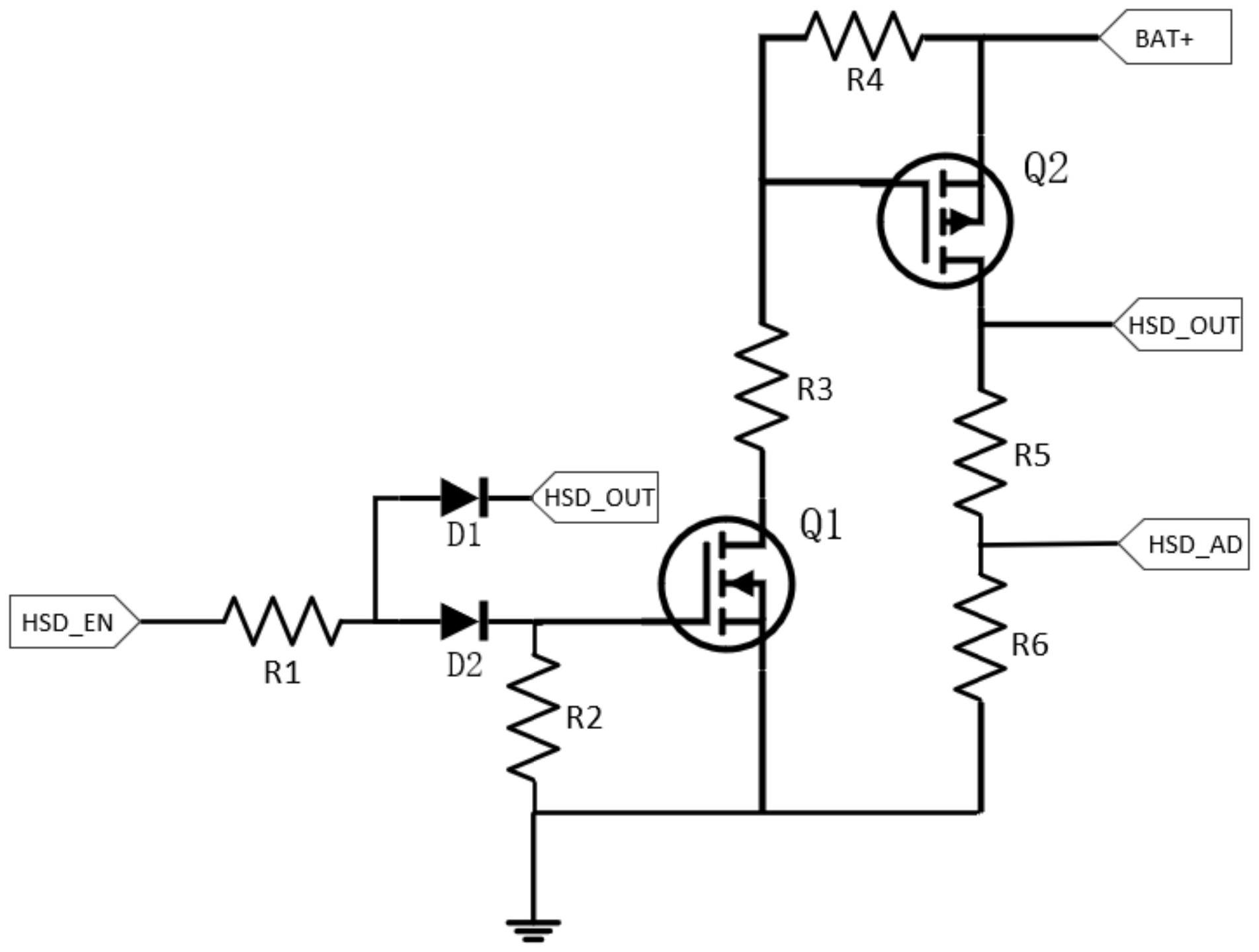

In the second part we will discuss safety hazards such as short circuits and wiring errors.Short circuits, a direct connection between two points in an electrical circuit can lead to a sudden current surge, causing severe damage to the power supply and connected equipment - in some cases, leading to a fire. Incorrect Wiring can result in arcing, overheating, or short circuits. Miswiring power supplies can also cause immediate equipment failure.

Finally, there isInadequate Insulation and leakage current. Insulation protects against electrical hazards, but it can degrade over time from wear and environmental conditions. This increases the risk of short circuits and electrical shock. Leakage current refers to unintended current flow through the insulation or external parts of a power supply. It can pose a shock hazard, especially when sensitive equipment or personnel are involved.

Although we are not professionals and cannot directly repair the power supply, and may not be able to detect problems with the power supply in a timely manner, we can still prevent problems with our power supply by taking the following measures.In fact, modern power supplies are carefully regulated by an array of organizations, from UL to IEC, CSA, CE, and more. There are also power supply safety precautions taken for isolation and insulation.While adhering to standards and certifications is crucial, implementing additional best practices during the design and integration of power supplies further enhances safety.

Ensuring power supply safety requires attention to several critical factors. Proper grounding is essential, particularly for Class I power supplies, as inadequate grounding can lead to electrical faults, increasing the risk of shock or fire. Environmental protection is another key consideration, especially for systems operating in extreme conditions such as high humidity, dust, or outdoor settings, where power supplies must be appropriately rated and housed in protective enclosures to prevent damage and reduce the risk of hazardous failures. Thermal management is equally important, as overheating is a common cause of power supply failure, and implementing adequate cooling solutions, such as heat sinks or fans, helps maintain optimal operating temperatures while prolonging the lifespan of the power supply. Additionally, regular maintenance is crucial, particularly in industrial or medical settings, where power supplies should undergo routine inspections to ensure proper functionality, as insulation may degrade over time, connections may loosen, and environmental factors may impact performance.

Power supply safety is a multifaceted challenge that requires careful consideration of IEC protection ratings and safety certifications such as UL and CE. When it comes to power supply safety, understanding the details of certification and protection standards is fundamental. Please be sure to review the relevant safety reports and ensure that the power supply you choose is compatible with the operating environment. This will help you avoid unnecessary risks and ensure the long-term success of your product. Additionally, as mentioned earlier, we have highlighted a series of common issues and preventive measures. We fully understand the importance of designing power supplies that meet these stringent safety requirements. By selecting the appropriate power supply and adhering to industry best practices, you can not only ensure your system achieves optimal performance but also guarantee the safety of both users and equipment.