1. Overview of the High-Voltage Power Supply for Electrostatic Bag Composite Dust Collectors

The performance of the high-voltage power supply for an electrostatic bag composite dust collector significantly impacts dust removal efficiency. Generally speaking, the dust removal efficiency of the electrical zone of an electrostatic bag composite dust collector depends on the dust propagation velocity, which in turn is determined by the charging electric field strength and the dust collection electric field strength. To achieve higher dust removal efficiency, the propagation velocity must be maximized, which means the electric field strength in the electrical zone of the dust collector must be maximized. The requirements for the high-voltage power supply for an electrostatic bag composite dust collector are as follows: The high-voltage power supply must be able to quickly adapt to changes in dust collector operating conditions, automatically adjusting output voltage and current parameters to ensure optimal operation of the electrostatic bag composite dust collector at optimal voltage and current levels. The high-voltage power supply must be able to quickly identify and respond to flashover, arcing, and overcurrent signals, providing necessary protection in the event of a fault in the electrostatic bag composite dust collector.

With the continuous advancement of high-voltage power supply technology and the emergence of new technologies, key domestic environmental protection companies have developed a number of new high-voltage power supply systems through independent research and development and technology imports to keep pace with the development of the electrostatic bag composite dust collector market. Currently, common high-voltage power supply products in China include conventional power supplies, high-frequency power supplies, three-phase high-voltage power supplies, LC constant-current high-voltage power supplies, pulse power supplies, and plasma power supplies. Longking Environmental Protection has extensive and mature experience in the application of conventional and high-frequency power supplies in electric bag composite dust collectors.

2. Special Features of High-Voltage Power Supplies for Electric Bag Composite Dust Collectors

The high-voltage power supply is a crucial component of electric bag composite dust collectors. Improving power efficiency can effectively improve the overall operating efficiency of the equipment. Based on current experience with electric bag composite dust collectors, this article recommends the use of high-frequency high-voltage power supplies and single-phase industrial frequency high-voltage power supplies. Other types of high-voltage power supplies are also acceptable, and DC power supply is preferred. High-voltage power supplies can be supplied by electric field or by zones. When using zoned power supply, each high-voltage power supply can simultaneously power multiple zones, and each zone should be easily deactivated.

Compared to electrostatic precipitators (ESPs), the pre-electric field in an electrostatic bag composite dust collector has unique process functions, and its high-voltage power supply has its own particularities, resulting in many differences. These differences are detailed below:

2.1 Selection of High-Voltage Power Supply Current and Voltage

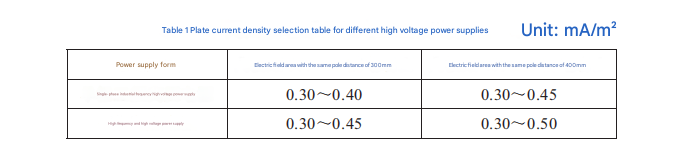

Based on the process of an ESP, its electric field zone has two primary functions: first, pre-charging dust in the flue gas to maximize the charge on dust particles; and second, pre-collecting dust. This requires a high operating current for the electric field. Conventional ESPs typically use a 300-400mm inter-electrode spacing in the electric field zone. The current capacity of the high-voltage power supply is selected based on the current density required to ensure dust charging intensity. This is determined based on the current density of the selected dust collecting plates and the total dust collection area of the electric field zone, with a certain design margin (generally 5%) taken into account. ESPs recommend a higher plate current density, with a design value between 0.3 and 0.5 mA/m². The plate current density selection for the electric field zone is shown in Table 1.

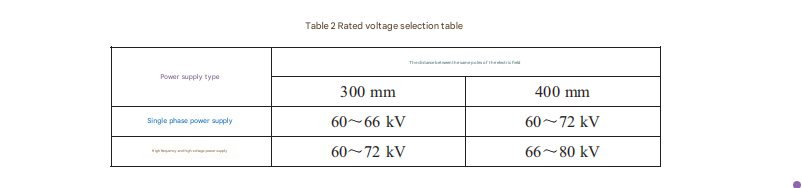

Because the electric field zone of an electrostatic bag composite dust collector is the front electric field, its voltage design should be between 60 and 80 kV, and the maximum current capacity of a single high-voltage power supply should be below 2.0 A. The average field strength during operation in the electric field zone is generally 3 to 4 kV/cm. That is, for an electric field with a 300 mm inter-pole spacing, the operating voltage of a single-phase power-frequency high-voltage power supply is generally 60 to 66 kV; for an electric field with a 400 mm inter-pole spacing, the operating voltage of a single-phase power-frequency high-voltage power supply is generally 60 to 72 kV. The rated voltage selection for different electric field and inter-pole spacings is shown in Table 2.

2.2 High-voltage Power Supply Current Control Characteristics Requirements

The electric field zone of an electrostatic bag composite dust collector requires a large operating current, which requires the high-voltage power supply to have good current control characteristics, stable operating voltage, and low ripple coefficient. The high-voltage power supply should operate under a DC-powered spark-tracking control mode. Therefore, the current and spark control characteristics of the high-voltage power supply must be excellent, and the operating voltage must be stable. This article significantly increases the spark rate to 200 times per minute. During high-voltage power supply commissioning, it is required to carefully select the transformer taps, adjust the spark characteristics, and maximize the operating current to ensure a high charging current in the electric field zone.

2.3 High-voltage Power Supply Alarm Function Requirements

If the electric field zone of an electric bag composite dust collector operates under low voltage and low current conditions for a long period of time, it will seriously affect the overall efficiency of the electric bag composite dust collector. Therefore, the high-voltage power supply must have a low-voltage and low-current alarm function. During the hot summer months, especially when the main electric field uses a strong spike pole, the high-voltage power supply operates with a high spark frequency and high operating current. Pay special attention to the proper functioning of the oil temperature detection and alarm functions to avoid transformer oil temperature overheating failures.

2.4 High-Voltage Power Supply Control Requirements

Traditional high-voltage power supplies, whether single-phase or high-frequency, are designed and manufactured for use with electrostatic precipitators (ESPs). Many of the features designed for ESPs, such as intermittent power supply, pulse power supply, and energy-saving mode, are not applicable to ESPs. Therefore, the control functions of the high-voltage power supply for ESPs must be specifically optimized. It is recommended that the high-voltage power supply for ESPs operate in full-wave DC power supply mode, pure DC power supply mode, spark tracking control mode, optimal spark rate mode, and other modes that increase average voltage and average current. Other control modes for ESPs, such as intermittent power supply and pulse operation, are not recommended.

2.5 High-Voltage Power Supply Reliability Requirements

The electric field region of an ESP is generally the front electric field, with only one or two electric fields. The performance of the high-voltage power supply is closely related to the resistance of the filter bag area and the life of the filter bags. In particular, the high-voltage power supply must be robust, stable, and reliable in dust charging. Therefore, compared to electrostatic precipitators, the reliability requirements of the high-voltage power supply for an electrostatic bag filter are higher. When the resistance in the filter bag area increases significantly, the high-voltage operating status should be checked to see if there are any high-voltage trips or drops in high-voltage voltage or current (caused by reduced efficiency in the electric field or insufficient dust charging).

The single-unit high-voltage power supply operation rate is required to reach at least 99.6%. For example, for a 6,000-hour annual operating time, only 24 hours of downtime is permitted. Here, the single-unit operation rate = [(equipment expected operating time - equipment downtime due to failures) / equipment expected operating time] × 100%.

3 Conclusion

In summary, as a new type of dust collector, the electrostatic bag filter has significant differences in dust removal processes and high-voltage power supply technical requirements compared to electrostatic precipitators. In the future, these differences will become increasingly significant as both electrostatic bag filter and electrostatic precipitators develop. This article provides a transparent interface for selecting power supplies for electrostatic bag filters, guiding the healthy development of the power supply industry and promoting technological advancement.

Share our interesting knowledge and stories on social media