Cars are changing fast. They are becoming electric, smart and connected. This means the electronic systems in cars are getting more complicated. Things like Advanced Driver Assistance Systems and infotainment units and also Battery Management Systems and lots of sensors. They all need power to work properly.

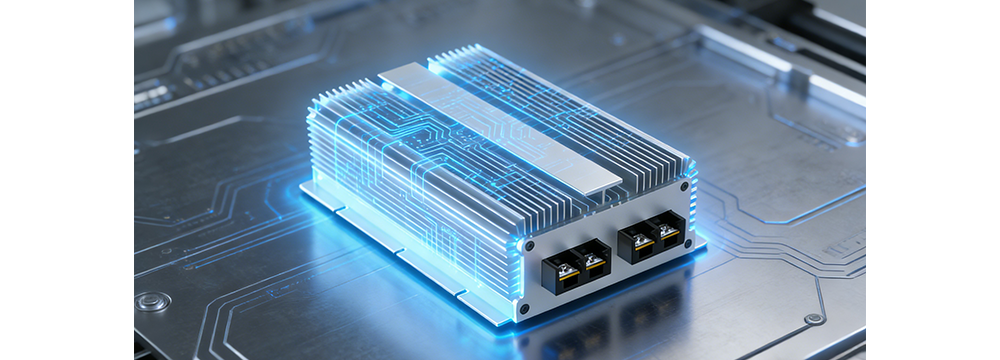

DC-DC converters are very important because they help get power from the batteries in cars to the smaller electronic systems that need it. They are, like a bridge that helps get energy where it is needed. DC-DC converters are really necessary now.

The automotive world has its set of needs. These needs make it really tough to design and use DC-DC converters. This article is going to look at the problems that come up. It will also talk about what the industry's doing right now to deal with these problems. The automotive world and its needs are what make it so hard to work with DC-DC converters.

1. Extremely Wide Input Voltage Range: Surviving from 6V to 75V

In traditional 12V lead-acid battery systems, voltage can dip below 6V during cold cranking, while transient events like load dump can cause surges up to 60V or even 75V. In electric vehicles (EVs), main traction battery platforms operate at 400V or 800V, requiring isolated or non-isolated DC-DC converters to step down voltage to 12V or 48V for low-voltage subsystems.

Design challenges:

The converter must maintain a stable output across the entire input range;

High-voltage transients place stringent requirements on component voltage ratings (e.g., MOSFETs, capacitors);

Topology selection is constrained—designs often require Buck-Boost, SEPIC, or full-bridge configurations.

Solution: Use wide-input-range controller ICs (e.g., TI’s LM5185 or ADI’s LT8390) combined with front-end TVS diodes or pre-regulation circuits to suppress transient overvoltages.

2. Functional Safety and High Reliability: A Non-Negotiable “Lifeline”

Automotive electronic devices must comply with the ISO 26262 functional safety standard. Since a failure in the DC-DC power supply can cause systems such as the electric power steering or braking control system to stop working, the DC-DC power supply is a critical component of automotive electronic devices.

Key requirements:

Integrated protection mechanisms: Over-Voltage Protection (OVP), Under-Voltage Lockout (UVLO), Over-Current Protection (OCP), and Over-Temperature Protection (OTP);

Support for fault diagnostics and safe-state transitions:

The AEC-Q100 automotive qualification standards are very important,and all components must follow them.

3. Electromagnetic Compatibility (EMC): The Enduring Battle Against Noise

DC-DC converters operate at high frequencies like 200 kHz to 2 MHz. These DC-DC converters are sources of bad electromagnetic interference or EMI for short in vehicles. This bad noise from the DC-DC converters can get into sensitive circuits in two ways: it can travel through things that conduct electricity or it can radiate through the air. When this noise from the DC-DC converters gets into these circuits it can cause a lot of problems such as:

* Radio static from the DC-DC converters

* Loss of GPS signal due to the DC-DC converters

* Errors, in CAN bus communication because of the DC-DC converters

Core challenges:

There is not a lot of room so we cannot use filters and shielding like we want to. We have to make do with space and that restricts the use of filters and shielding.

When you have a lot of DC-DC modules working at the time they can really interfere with each other. This is because the DC-DC modules can affect one another. The more DC-DC modules you have operating the worse the interference, from the DC-DC modules gets.

Mitigation strategies:

Optimize PCB layout: minimize high-current loop areas and separate analog/digital grounds

Implement Spread Spectrum Frequency Modulation (SSFM) to disperse EMI energy

We need to add some filters called π-type LC filters and common-mode chokes to the input and output stages. The π-type LC filters and common-mode chokes will be added to these stages to help with the performance of the system. The π-type LC filters will play a role in this. We will use the π- LC filters and common-mode chokes at the beginning and end of the system.

4. Thermal Management vs. High Power Density: A Fundamental Trade-off

The temperature under the hood of a car can get really hot. Go over 125°C. This is a problem because most cars do not have fans to cool things down they just use air to cool them. At the time the companies that make cars want the parts that go in them, like the automotive applications to be smaller and more powerful. The automotive applications need to be able to handle the temperatures and still work properly.

Typical dilemmas:

High efficiency is not the same, as zero loss. The extra heat that is left over still needs to be gotten rid of in a way;

Synchronous rectification makes things more efficient. However it also brings some problems like gate drive losses and thermal coupling. Synchronous rectification is a thing, for efficiency but it has these other issues.

So when we make things smaller, like miniaturization the surface area gets really small too. This means that heat has a time getting out which increases the thermal resistance of the miniaturization. The miniaturization makes it tough for heat to dissipate. That is a problem because it affects the miniaturization.

Innovations:

Use metal-core PCBs (IMS) or embedded copper pillars to enhance thermal conductivity;

Adopt wide-bandgap semiconductors like GaN (gallium nitride) or SiC (silicon carbide) to reduce switching losses;

Employ thermal simulation tools early in the design phase to optimize heat flow paths.

5. Dynamic Load Response: Handling “Instantaneous” Transients

Modern automotive loads can change dramatically in microseconds—for example, when a millimeter-wave radar powers on or an infotainment system switches from sleep to high-definition playback. The DC-DC converter must maintain output voltage stability within microseconds.

Limitations of traditional approaches:

Voltage-mode control has limited bandwidth and slow response;

Fixed compensation networks struggle to adapt to varying load conditions.

Advanced solutions:

Current-mode control simplifies the system to a single-pole response, improving stability and speed;

Adaptive frequency modulation or digital PID control dynamically tunes loop parameters based on load;

Local energy buffering using bulk capacitors or supercapacitors smooths transient current demands.

6.Challenges as Opportunities

In the world of car electronics DC-DC converters are not just devices that control voltage anymore. They are really systems that combine electronics, heat management, safety from interference and making sure everything works safely. The people who make these things have to deal with tough conditions and they need to make them work better and better. So they are using materials like GaN and SiC and new ways of designing them like soft-switching and interleaved multiphase. They are also using control methods, like adaptive digital loops and using artificial intelligence to predict what might happen with the DC-DC converters.

As 800V architectures enter the mainstream and software-defined vehicles gain ground in the years ahead, DC-DC converters are set to transform—from passive power supplies into intelligent nodes within the vehicle-wide energy network. Addressing these hurdles is critical for any automotive electronics engineer chasing excellence in next-generation design.

Share our interesting knowledge and stories on social media