IGBT (Insulated Gate Bipolar Transistor) is a core device in the field of modern power electronics. It plays a key role in many fields with its unique structure and excellent performance. Its working principle is based on the perfect combination of high input impedance and low conduction loss achieved by the insulated gate structure. Through the fine control of the gate voltage, the IGBT can quickly switch the circuit state and achieve efficient power conversion.

This article will deeply analyze the principle of IGBT and explore its important role in practical applications, in order to provide readers with a comprehensive understanding of IGBT technology.

The concept of IGBT

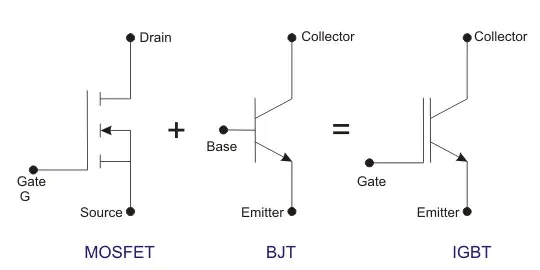

IGBT is an advanced power electronic device that combines the advantages of high input impedance of field effect transistor (MOSFET) and high current density of bipolar transistor (BJT).

IGBT controls its on and off states through gate voltage to achieve fast and efficient conversion of electric energy. It has the characteristics of low conduction loss, high voltage resistance and fast switching speed, so it is widely used in energy conversion, motor control, industrial automation and other fields.

Whether it is wind power generation, electric vehicle charging system, or industrial automation production line, IGBT plays a vital role and promotes the continuous development and progress of modern power electronics technology.

Structure of IGBT

Overall structure IGBT (insulated gate bipolar transistor) is a hybrid power semiconductor device. Its overall structure includes N-P-N structure, which is divided into N-channel, P-substrate and N-drain region. The gate controls the flow of current and controls the conductivity of the channel region by adjusting the gate voltage.

The insulating layer isolates the gate and channel region to prevent current leakage. Electrons enter the P-substrate from the N-channel to form a current. Compared with BJT, IGBT reduces the base current and improves efficiency.

Basic components

The N-channel is an N-type semiconductor region that controls the flow of current. The P-substrate is a P-type semiconductor region that provides a reference voltage. The N-drain region is located between the N-channel and the P-substrate and is responsible for carrying current.

The gate is connected to the N-channel through an insulating layer, and the conductivity of the N-channel is controlled by adjusting the gate voltage. Electrons enter the P-substrate from the N-channel to form a current, thereby completing the function of a power switch.

The combination of these three regions gives the IGBT the high input impedance of a MOSFET and the high current carrying capacity of a BJT, making it suitable for high-efficiency power control applications.

Gate structure

The gate structure of an IGBT is a key part of controlling the flow of current. The gate is located above the insulating layer and is directly connected to the N-channel.

The conductivity of the N-channel can be adjusted by applying a positive or negative voltage to control the gate. When a positive voltage is applied to the gate, electrons are attracted to the N-channel, increasing conductivity; conversely, when a negative voltage is applied, electrons are repelled, reducing conductivity.

This control capability allows the IGBT to flexibly adjust the flow of current and achieve precise power control. At the same time, the existence of the insulating layer effectively isolates the gate from the N-channel to prevent current leakage. The design of the gate structure affects the performance and response speed of the IGBT, which is of great significance for power switch applications. Insulation layer The insulating layer is located between the gate and the N-channel, playing the role of isolation and protection.

It is usually composed of materials such as silicon oxide, which has high insulation performance and can effectively prevent current leakage between the gate and the N-channel. The thickness and quality of the insulating layer directly affect the performance and stability of the IGBT. The greater the thickness, the better the insulation effect, but it will also increase the voltage drop and response time of the device.

Therefore, it is necessary to balance the thickness and performance requirements of the insulating layer during the design process. The optimization of the insulating layer can improve the voltage resistance and anti-interference ability of the IGBT, thereby improving the reliability and stability of the device, and is widely used in power electronics, drives, inverters and other fields.

Current carrying area

The current carrying area is a key part of the IGBT, consisting of the N-channel and the P-substrate. The N-channel is an N-type semiconductor region responsible for the transport of electrons; while the P-substrate is a P-type semiconductor region that provides a reference voltage. When the gate applies voltage, the electrons in the N-channel are controlled to form a current.

The electrons enter the P-substrate through the N-channel to complete the current carrying function. The design of the current carrying area affects the conduction characteristics and power loss of the IGBT, and needs to be optimized in terms of voltage drop, current density and heat distribution. At the same time, the current carrying area is also the key to the voltage and high temperature resistance of the IGBT, and its structure and material selection directly affect the performance and reliability of the device.

Principle of IGBT

IGBT combines the advantages of MOSFET and BJT. It consists of N-channel, P-substrate and N-drain region. When the gate applies voltage, the conductivity of the N-channel is controlled to control the current flow. Electrons enter the P-substrate from the N-channel to form a current and complete the power switching function.

IGBT has the high input impedance of MOSFET and the high current carrying capacity of BJT, and is suitable for high-efficiency power control applications. Its key features include low driving power, low conduction voltage drop and fast switching speed. It is widely used in power electronics, electric vehicles, UPS and inverters, and has promoted the development of energy transformation and industrial automation.

Application of IGBT

IGBT (Insulated Gate Bipolar Transistor) is a high-performance power semiconductor device that is widely used in many fields, including power electronics, industrial automation, transportation, telecommunications, and consumer electronics. The following is an overview of its main application areas:

1. Power electronics applications: IGBT is widely used in power converters such as AC-DC Converter, DC-AC Inverter, AC-AC Converter, etc., for the regulation and control of power systems, such as power frequency modulation and voltage regulation. In addition, IGBT also plays an important role in power transmission and distribution systems, used to adjust grid loads, improve grid stability and energy efficiency.

2. Industrial automation: IGBT is widely used in industrial automation equipment such as motor drives, variable frequency air conditioners, welding equipment, power tools, UPS (uninterruptible power supply), motor controllers, etc., to achieve precise power control and efficient energy utilization, and improve production efficiency and product quality.

3. Transportation: In the fields of transportation such as electric vehicles, high-speed railways, subways, and electric ships, IGBTs are used in motor drive systems and on-board inverters to achieve efficient energy conversion and precise speed control, promoting the development of electrified transportation.

4. Telecommunications: IGBTs are used in power inverters and battery chargers of telecommunication base stations to provide stable power supply and efficient energy conversion, ensuring the reliable operation of communication equipment.

5. Consumer electronics: IGBTs are widely used in the field of home appliances, such as variable frequency air conditioners, refrigerators, washing machines, etc., and improve the performance and energy saving of home appliances through precise power control and efficient energy utilization.