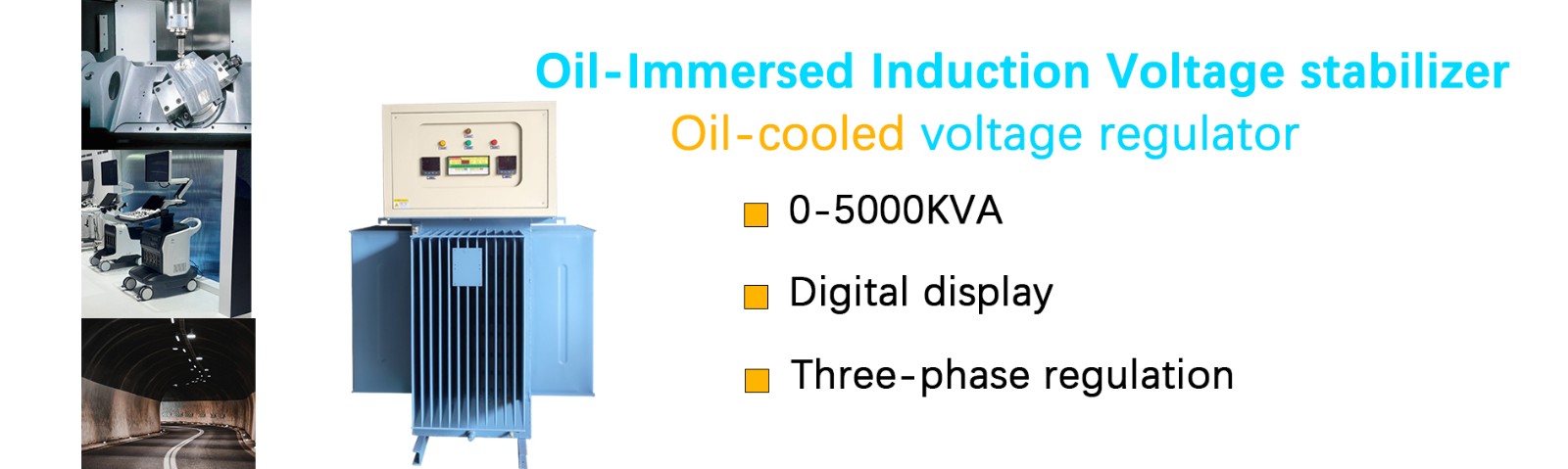

Oil-immersed voltage regulator Oil-immersed self-cooling induction voltage regulator Use: The induction voltage regulator can adjust the output voltage steplessly, smoothly and continuously under load. It is mainly used for motor and electrical testing, electric furnace temperature control, rectifier equipment matching, generator excitation, etc. Oil-immersed voltage regulator is widely used in machinery manufacturing, chemical industry, textile, communication, military industry and other industries.

Use

Oil-immersed voltage regulator Oil-immersed self-cooling induction voltage regulator Use: The induction voltage regulator can adjust the output voltage steplessly, smoothly and continuously under load. It is mainly used for motor and electrical testing, electric furnace temperature control, rectifier equipment matching, generator excitation, etc. Oil-immersed voltage regulator is widely used in machinery manufacturing, chemical industry, textile, communication, military industry and other industries.

Features

Features of oil-immersed voltage regulator:

1. Contactless regulation, long service life;

2. Suitable for loads of various properties;

3. Strong overload capacity;

Oil-immersed voltage regulator Reliable operation, easy to use and maintain

Induction voltage regulator The working principle and structure are similar to those of a locked asynchronous motor, while the energy conversion relationship is similar to that of an autotransformer.

It uses a transmission mechanism such as a handwheel or a servo motor to generate an angular displacement between the stator and the rotor, thereby changing the phase and amplitude relationship of the induced electromotive force between the stator winding and the rotor winding to achieve the purpose of adjusting the output voltage. Induction voltage regulators are available in three-phase and single-phase types.

Oil-immersed voltage regulator If the rotor position is changed, that is, the angle α is changed, the secondary output voltage U2 can be smoothly adjusted. The maximum and minimum output voltages are respectively The structure and voltage regulation function of the single-phase induction voltage regulator are similar to those of the three-phase induction voltage regulator, but its stator and rotor are both single-phase windings.

Since the induction voltage regulator has no sliding contacts, it is very reliable. However, it only rotates an angle during the voltage regulation process and does not rotate continuously, so the heat dissipation conditions are poor. Air cooling can be used for small capacity, and oil cooling is required for large capacity. The weight, excitation current and loss of the induction voltage regulator are greater than those of the autotransformer. Voltage regulator product use

It is suitable for urban residential area voltage regulating boxes (stations), and is also suitable for industrial users such as boilers, industrial furnaces, etc. that have different requirements for urban gas pressure.

Because the oil-immersed voltage regulator has no sliding contacts, it is very reliable. However, it only rotates an angle during the voltage regulation process and does not rotate continuously, so the heat dissipation conditions are poor. Air cooling can be used for small capacity, and oil cooling is required for large capacity. The weight, excitation current and loss of the oil-immersed voltage regulator are greater than those of the autotransformer.

Case 1:

This project is a provincial road construction project. Due to the large power of the inductive load, the mixing station causes a voltage drop of more than 100V due to excessive current at the start. Without voltage stabilization equipment, only 30% of the equipment can be turned on, resulting in low production efficiency and delaying production tasks.

The person in charge bought an ordinary mechanical voltage stabilizer in advance. Since the ordinary voltage stabilization speed is as high as 1S or more, it cannot respond to the voltage stabilization in time at the moment of startup, which makes it impossible to work at all and cannot solve the problem. Later, we found Baoyuan Electric Power. We recommend customers to choose a contactless voltage stabilizer.

The contactless voltage stabilizer has no mechanical structure and the voltage stabilization response time is 40 milliseconds, which can perfectly solve the problem (the biggest advantage of our contactless voltage stabilizer is that it can carry high-power inductive loads, which is not available in other contactless voltage stabilizers). After understanding, the customer successfully reached an agreement to use the IDEALPLUSING power contactless voltage stabilizer.

After the on-site equipment is 100% turned on, even if the front-end instantaneous voltage drop exceeds 100V, the contactless voltage stabilizer can still ensure the output voltage stability in milliseconds, and the equipment will not suddenly stop in the sound field.

Case 2:

This project is a pig farm. Due to its large scale and the number of pigs in the farm is 1000+, there are many electrical equipment and most of them are inductive equipment. After on-site observation and measurement, we found that the three-phase voltage can reach 400V when the equipment is not turned on.

After the equipment is turned on one by one, the three-phase voltage drops sharply. After about 30% of the load is turned on, the three-phase voltage has dropped to 230V. The centralized control equipment of the pig farm began to alarm and no more equipment could be turned on.

After actual measurement, it was found that the pig farm is about 2 highways away from the village transformer. Based on the above information, the technical department of Guangdong Baoyuan Electric Power held a meeting and found that due to the large voltage drop at the back end, the cost of turning on 100% of the load at the same time is too high and exceeds the customer's expected price.

After sufficient communication with the customer, the target of turning on the load at the same time was set at 80%, and finally a set of solutions was determined. It was successfully achieved that 80% of the pig farm load equipment can be turned on at the same time, achieving the predetermined goal and successfully helping the customer solve the electricity problem.