An on-board DC/DC converter is a device that converts the high-voltage dc converter power supply of an electric vehicle's power battery pack into a constant low-voltage DC power. The function of this converter is equivalent to that of a generator and regulator in a traditional fuel vehicle. Its power comes from the vehicle's power battery pack, and it mainly powers low-voltage on-board electrical appliances, such as the power steering system, instrument panel, and other auxiliary equipment.

When choosing an car dc dc converter, what are the main technical indicators of the car that need to be considered? Let's discuss it below.

Input and output voltage range

The voltage range refers to the range of input voltage and output voltage that the on-board dc converter can accept. Usually, the input voltage range is between 6V and 28V, while the output voltage range is determined according to the specific application requirements, and the common ones are 5V, 12V, 19.2V, etc.

Output current capability

The output current capability refers to the maximum output current that the dc dc converter car converter can provide. This indicator directly affects the power requirements of the automotive electronic system.

Power level

Vehicles of different levels may have great differences in configuration, which will cause changes in the dynamic power requirements of the 14V system. Therefore, it is necessary to select a DC/DC converter with a suitable power level according to the vehicle level. For example, passenger cars are usually equipped with 1.5KW-2KW dc dc converter design, while buses may require 3KW-5KW high-power DC/DC converters.

Conversion efficiency

This is an important indicator of the dc dc converter, which determines the utilization rate of the vehicle's electric energy and also affects the heat dissipation method and service life of the entire component. At present, some advanced DC/DC converters, such as the dc dc converter efficiency produced by Dilong New Energy, generally have a conversion efficiency of more than 90%, and some products even reach 95%.

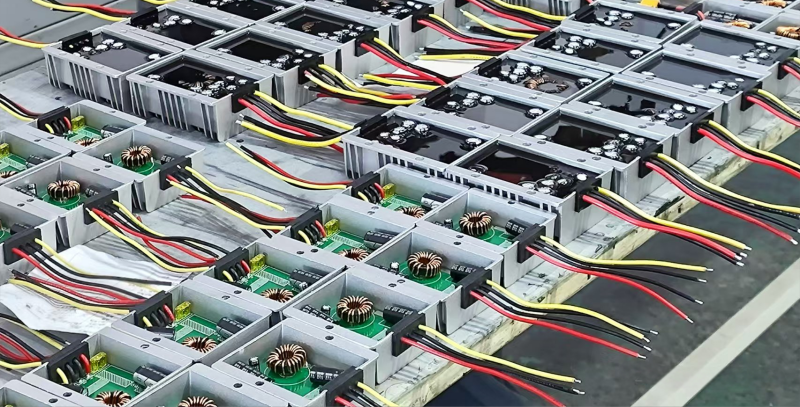

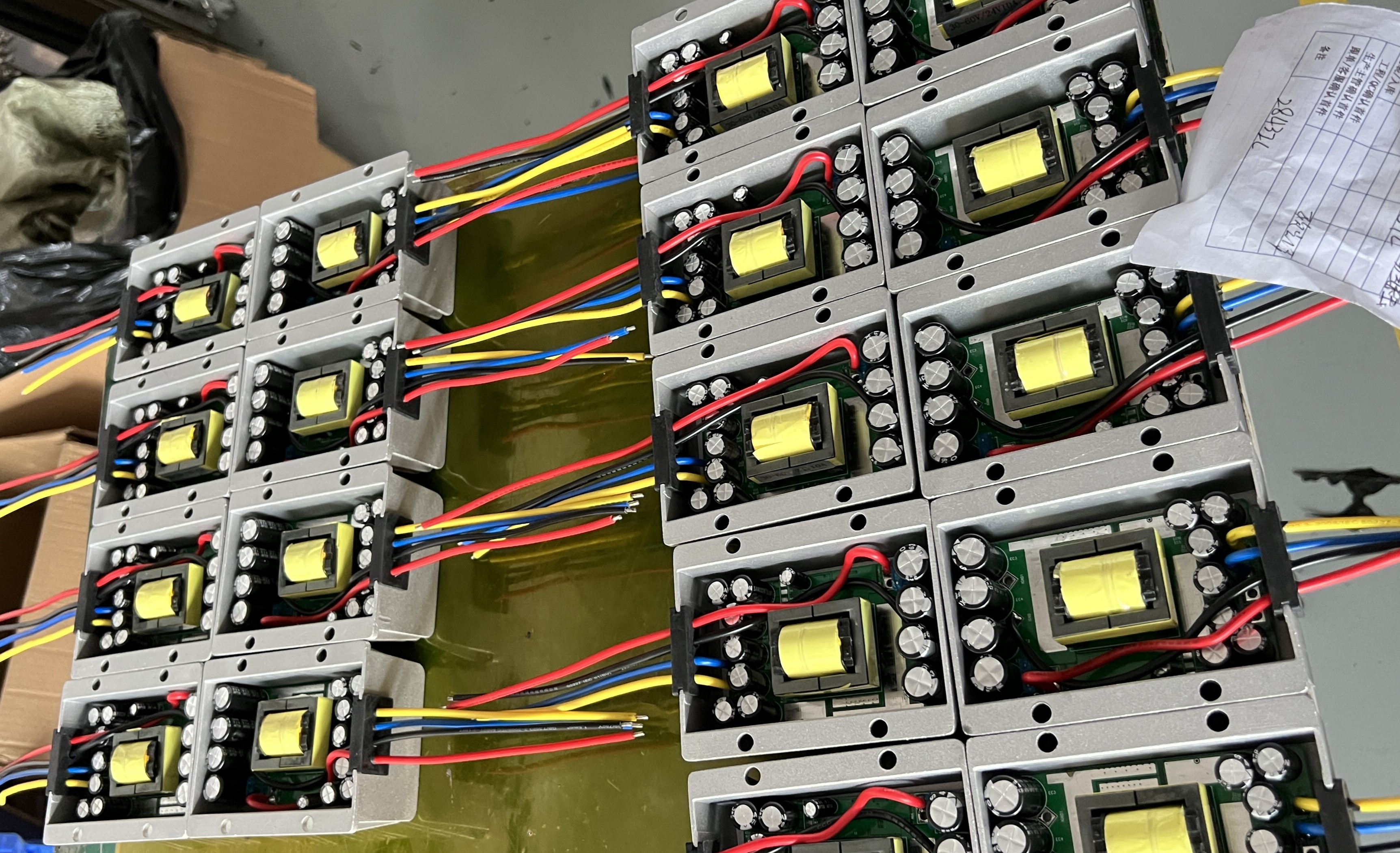

Volume, weight and power density

Due to the limited overall space of electric vehicles, the smaller the volume and higher the power density of the DC/DC converter, the more beneficial it is to save space for the entire vehicle. At present, the mainstream design trend is to integrate the DC/DC converter with other components to increase power density and reduce volume.

Heat dissipation method

Like most power electronic components, DC/DC converters have two heat dissipation methods at the power level of about 2KW: active air cooling and liquid cooling. Which heat dissipation method to choose depends on the specific needs and design of the system.

Cost

Considering that the cost requirements of automotive components are very strict, the cost factor needs to be fully considered when designing the DC/DC converter to maximize economic benefits.

In addition, the DC/DC converter should also have the characteristics of stable and reliable operation, long service life, and high safety to meet the high requirements of electric vehicles for component performance. At the same time, it should also meet the needs of the complex operating environment of the whole vehicle and have IP67 dust and water resistance.

Summary

When selecting an dc dc converter for electric vehicle, it is necessary to consider the characteristics of the vehicle, such as maximum speed, acceleration per 100 kilometers, weight, maximum torque and power conditions (peak power, continuous power, etc.). In addition, since the output voltage of the fuel cell stack is unstable, it can be boosted and stabilized through the closed-loop control of the DC/DC converter, and then supplied to the motor driver. Therefore, the on-board DC/DC converter plays an important role in both electric vehicles and fuel cell vehicles.